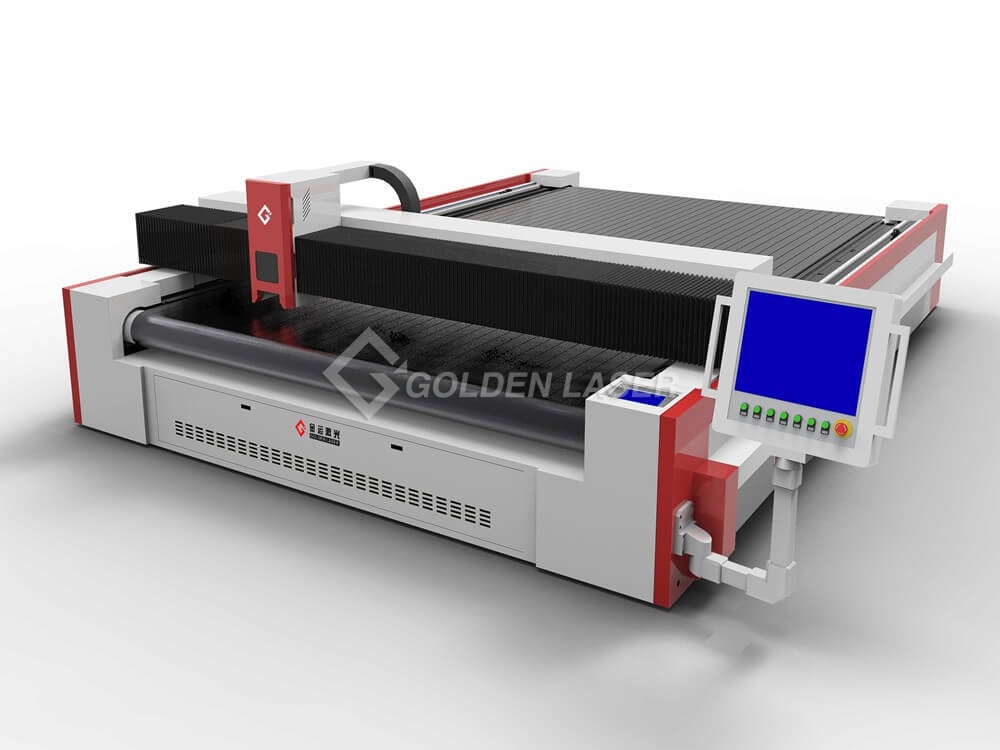

CO2 Laser Cutting Machine for Technical Textile

Model No.: JMCCJG-250300LD

Introduction:

- High-precision gear and rack driven, speed up to 1200mm/s, acceleration 8000mm /s2, and can maintain long-term stability

- World-class CO2 laser source

- Process textiles directly from the roll thanks to the conveyor system

- Auto feeder with tension correction

- Japanese Yaskawa servo motors

- Control system customized for industrial fabrics

Introduction

The JMC Series laser cutting machine is the professional solution for the laser cutting of textiles. Besides, the automatic conveyor system enables the possibility to process textiles directly from the roll.

By doing previous cutting tests with your individual materials, we test which laser system configuration would be the most suitable for you in order to achieve optimum results.

The Gear & Rack Driven Laser Cutting Machine is upgraded from the basic belt driven version. The basic belt driven system has its limitation when running with high power laser tube, whereas the Gear & Rack driven version is strong enough to undertake the high power laser tube. The machine can be equipped with high power laser tube up to 1,000W and flying optics to perform with super high acceleration speed and cutting speed.

Specification

Technical Specifications of the JMC Series Gear & Rack Driven Laser Cutting Machine

| Working area (W × L): | 2500mm × 3000mm (98.4'' × 118'') |

| Beam delivery: | Flying optics |

| Laser power: | 150W / 300W / 600W / 800W |

| Laser source: | CO2 RF metal laser tube / CO2 DC glass laser tube |

| Mechanical system: | Servo driven; Gear & rack driven |

| Working table: | Conveyor working table |

| Cutting speed: | 1~1200mm/s |

| Acceleration speed: | 1~8000mm/s2 |

Options

Optional extras simplify your production and increase the possibilities

Four Reasons

to Choose GOLDEN LASER JMC SERIES CO2 Laser Cutting Machine

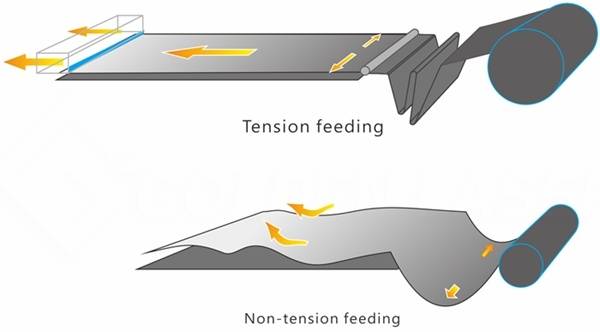

1. Precision tension feeding

No tension feeder will easy to distort the variant in the feeding process, resulting the ordinary correction function multiplier. Tension feeder in a comprehensive fixed on both sides of the material at the same time, with automatically pull the cloth delivery by roller, all process with tension, it will be perfect correction and feeding precision.

2. High-speed cutting

Rack and pinion motion system equipped with high-power CO2 laser tube, reaches to 1200 mm/s cutting speed, 12000 mm/s2 acceleration speed.

3. Automatic sorting system

- Fully automatic sorting system. Make the feeding, cutting and sorting of materials at one go.

- Increase the processing quality. Automated unloading of the completed cut parts.

- Increased level of automation during the unloading and sorting process also accelerates your subsequent manufacturing processes.

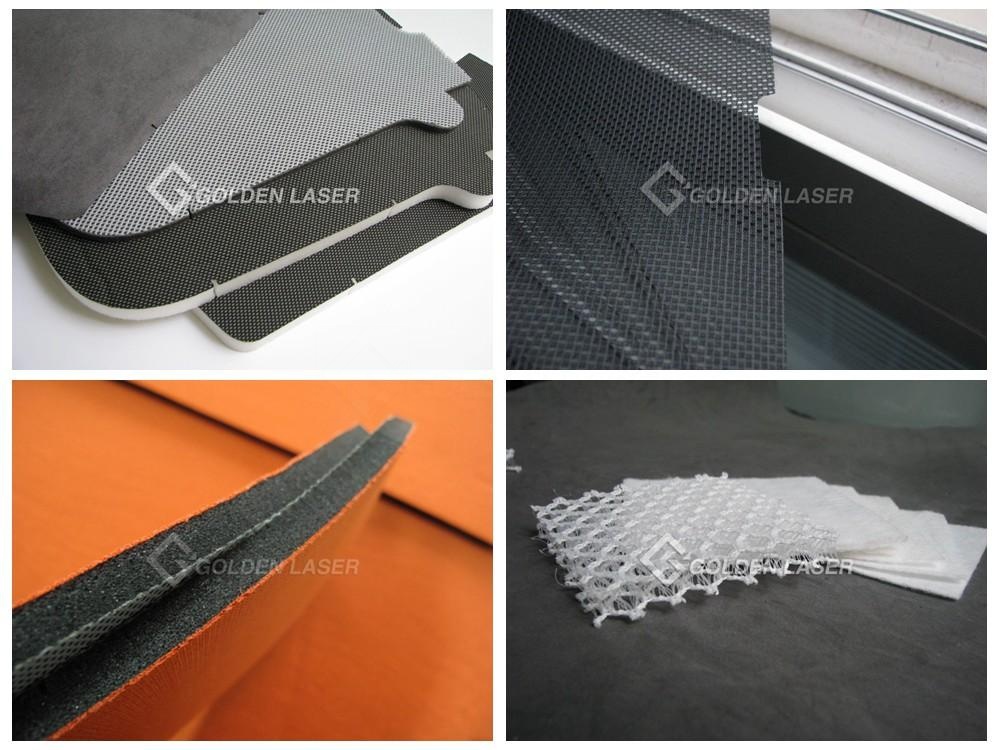

Laser cutting of technical textiles

CO2 lasers can cut a variety of fabrics quickly and easily. Suitable for laser cutting materials as different as filter mats, polyester, non-woven fabrics, glass fibre, linen, fleece and insulation materials, leather, cotton and more.

The advantages of lasers over traditional cutting tools:

Watch JMC Series CO2 laser cutter in Action!

Technical Parameter

| Laser type | CO2 laser |

| Laser power | 150W / 300W / 600W / 800W |

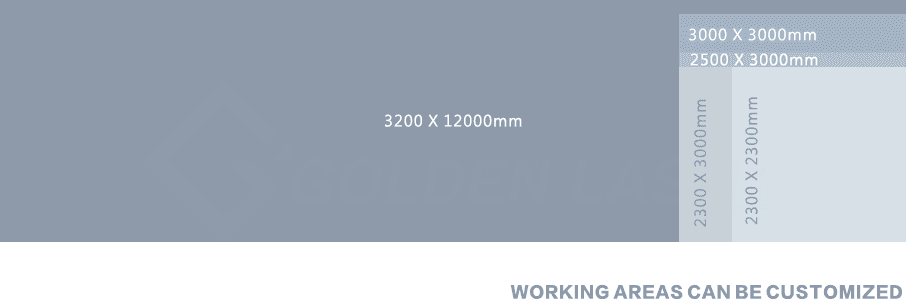

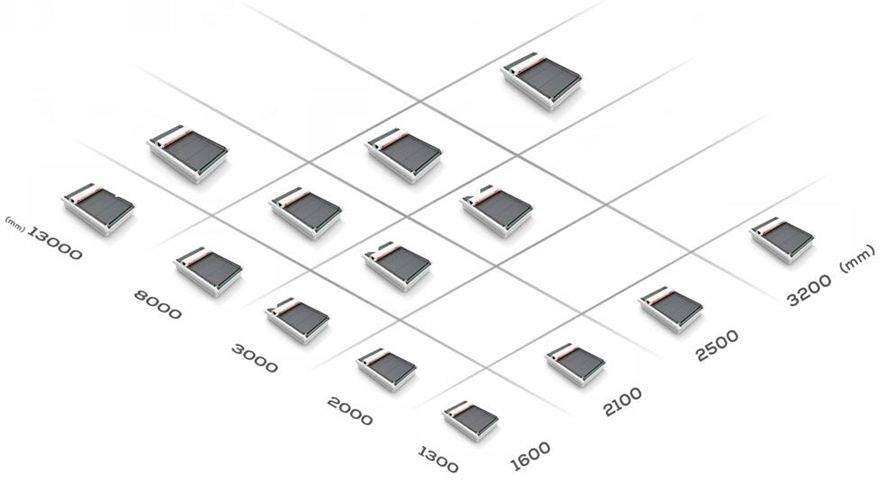

| Working area | (L) 2m~8m × (W) 1.3m~3.2m |

| (L) 78.7in~314.9in × (W) 51.1in~125.9in | |

| Working table | Vacuum conveyor working table |

| Speed | 0-1200mm/s |

| Acceleration | 8000mm/s2 |

| Repeat positioning accuracy | ±0.03mm |

| Positioning accuracy | ±0.05mm |

| Motion system | Servo motor, gear and rack driven |

| Power supply | AC220V±5% 50/60Hz / AC380V±5% 50/60Hz |

| Format supported | AI, BMP, PLT, DXF, DST |

| Lubrication system | Automatic lubrication system |

| Options | Auto feeder, red light position, marker pen, Galvo scan head, double heads |

GOLDEN LASER – JMC SERIES HIGH SPEED HIGH PRECISION LASER CUTTER

Working areas: 1600mm×2000mm (63″×79″), 1600mm×3000mm (63″×118″), 2300mm×2300mm (90.5″×90.5″), 2500mm×3000mm (98.4″×118″), 3000mm×3000mm (118″×118″), 3500mm×4000mm (137.7″×157.4″), etc.

***The cutting bed sizes can be customized according to different applications.***

Applicable Materials

Polyester (PES), viscose, cotton, nylon, nonwoven and woven fabrics, synthetic fibers, polypropylene (PP), knitted fabrics, felts, polyamide (PA), glass fiber (or glass fibre, fiberglass, fibreglass), Lycra, mesh, Kevlar, aramid, polyester PET, PTFE, paper, foam, cotton, plastic, 3D spacer fabrics, carbon fibers, cordura fabrics, UHMWPE, sail cloth, microfiber, spandex fabric, etc.

Applications

Industrial applications: filters, insulations, textile ducts, conductive fabric sensors, spacers, technical textile

Interior design: decorative panels, curtains, sofas, backdrops, carpets

Automotive: airbags, seats, interior elements

Military clothing: bulletproof vests & ballistic clothing elements

Large objects: parachutes, tents, sails, aviation carpets

Fashion: ornate elements, t-shirts, costumes, bathing & sports suits

Medical applications: implants & various medical devices

Textiles Laser Cutting Samples

Please contact goldenlaser for further infomation. Your response of the following questions will help us recommend the most suitable machine.

1. What is your primary processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process? What is the size and thickness of the material?

3. What is your final product? (application industry)