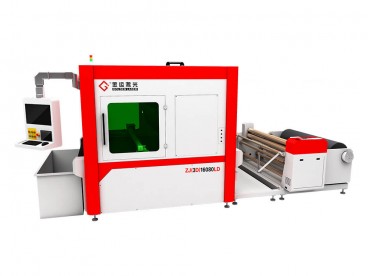

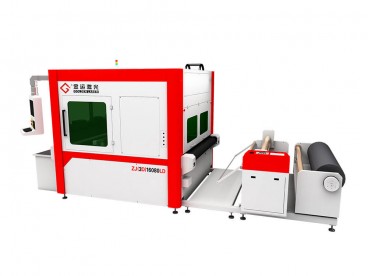

Textile Laser Machine with Two Galvo Scan Heads

Model No.: ZJ(3D)-16080LDII

Introduction:

The ZJ(3D)-16080LDII is an industrial CO2 laser machine designed to deliver exceptional performance for various textile fabrics, technical textiles, non-woven materials, and industrial fabrics. This machine stands out with its dual galvanometer heads and cutting on-the-fly technology, which allows simultaneous cutting, engraving, perforating, and micro-perforating while the material is continuously fed through the system.

The ZJ(3D)-16080LDII is a state-of-the-art CO2 Galvo laser machine with dual scan heads, designed for precise and efficient cutting and engraving of various textiles and fabrics. With a processing area of 1600mm × 800mm, this machine is equipped with an automatic feeding system featuring correction control, enabling continuous processing with high efficiency.

Technical Parameters

| Laser tube | Sealed CO2 laser source×2 |

| Laser power | 300W×2 |

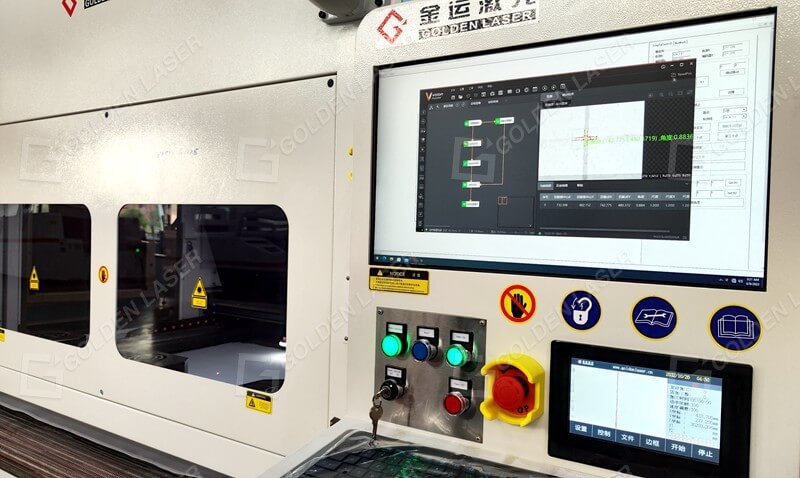

| Motion system | Servo system, safety alarm system, embedded offline control system |

| Cooling system | Water cooling |

| Cutting speed | 0~36000mm/min (depending on material, thickness and laser power) |

| Repeat positioning accuracy | ≤0.1mm/m |

| Laser direction | Perpendicular to the working table |

| Software | GOLDENLASER Cutting Software |

| Working table | Chain conveyor working table |

| Power supply | AC380V±5%, 50HZ / 60HZ |

| Dimensions | 6760mm×2350mm×2220mm |

| Weight | 600kg |

| Standard configuration | Upper blowing system, lower exhaust system |

Golden Laser’s CO2 Galvo Laser Machines Overview

Textile Laser Machine with Two Galvo Scan Heads ZJ(3D)-16080LDII

Full Flying Galvo Laser Cutting and Marking Machine with Camera ZJJG-16080LD

Galvo & Gantry Laser Engraving Cutting Machine JMCZJJG(3D)170200LD

Roll to Roll Flying Fabric Laser Engraving Machine ZJJF(3D)-160LD

SuperLAB | X-Y Gantry & Galvo laser machine with CCD Camera ZDJMCZJJG-12060SG

Galvo Laser Engraving Machine ZJ(3D)-9045TB

Applicable Industries

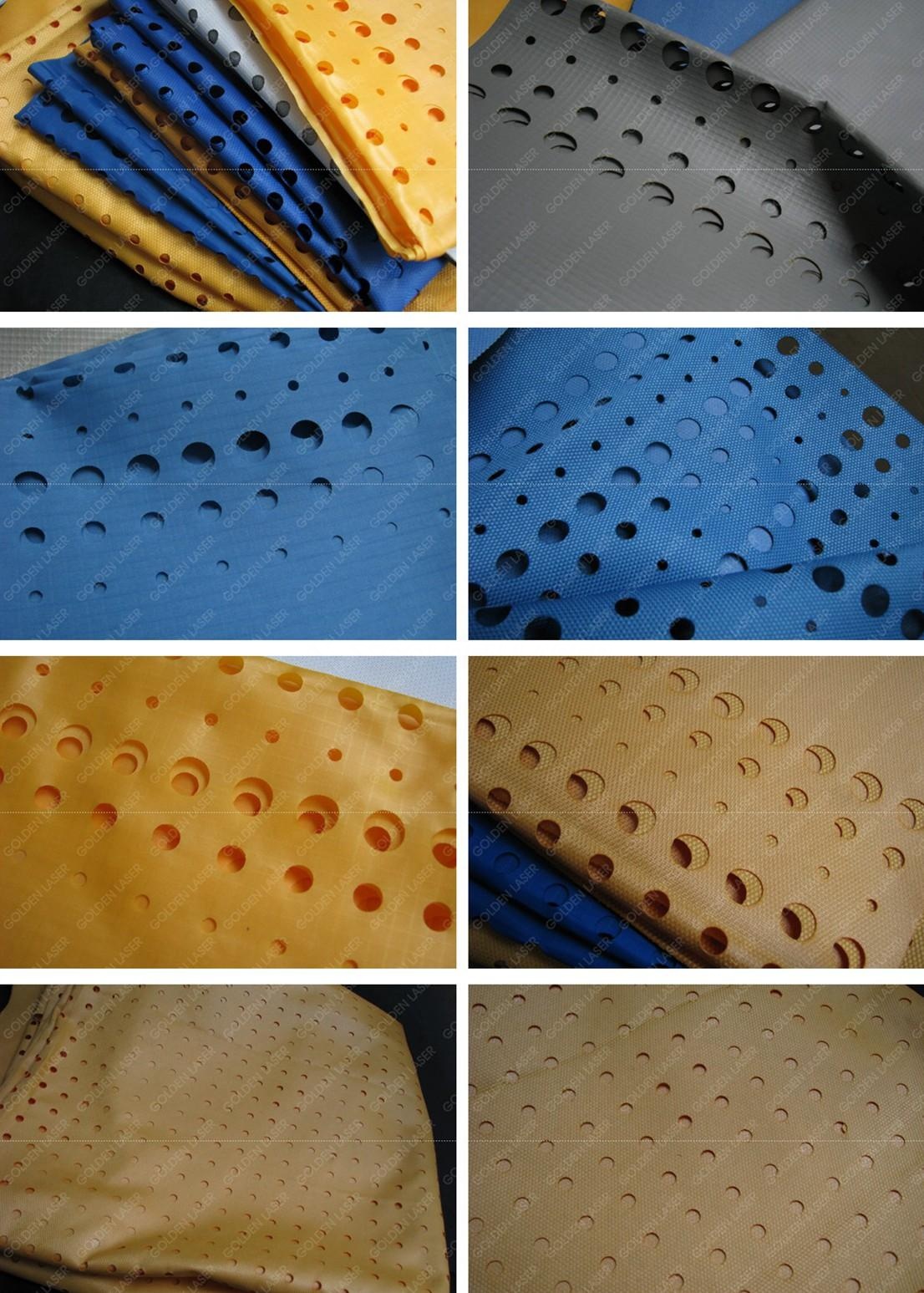

• Ventilation Ducts (Fabric Air Ducts): Perfect for perforating and cutting materials used in fabric air ducts for air dispersion systems.

• Filtration Industry: Processing of non-woven and technical fabrics used in air, liquid, and industrial filtration systems.

• Automotive Industry: Used for processing interior materials such as seat covers, upholstery fabrics, and non-woven materials.

• Industrial Fabrics: Ideal for processing durable, high-performance fabrics used in industrial applications such as heavy-duty covers, tarps, and belts.

• Outdoor Products: Suitable for cutting fabrics used in outdoor equipment such as tents, backpacks, and performance gear.

• Textile and Apparel Industry: Ideal for cutting and engraving fabrics used in fashion, home textiles, and technical textiles.

• Furniture and Upholstery: Suitable for cutting fabrics and materials used in furniture production, including upholstery and decorative fabrics.

• Sportswear and Activewear: Precision cutting of breathable and high-performance fabrics for jerseys, athletic clothing, and shoes.

Laser Cutting Samples

Please contact Golden Laser for further information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (laser marking) or laser perforating?

2. What material do you need to laser process? What is the size and thickness of the material?

3. What is your final product (application industry)?