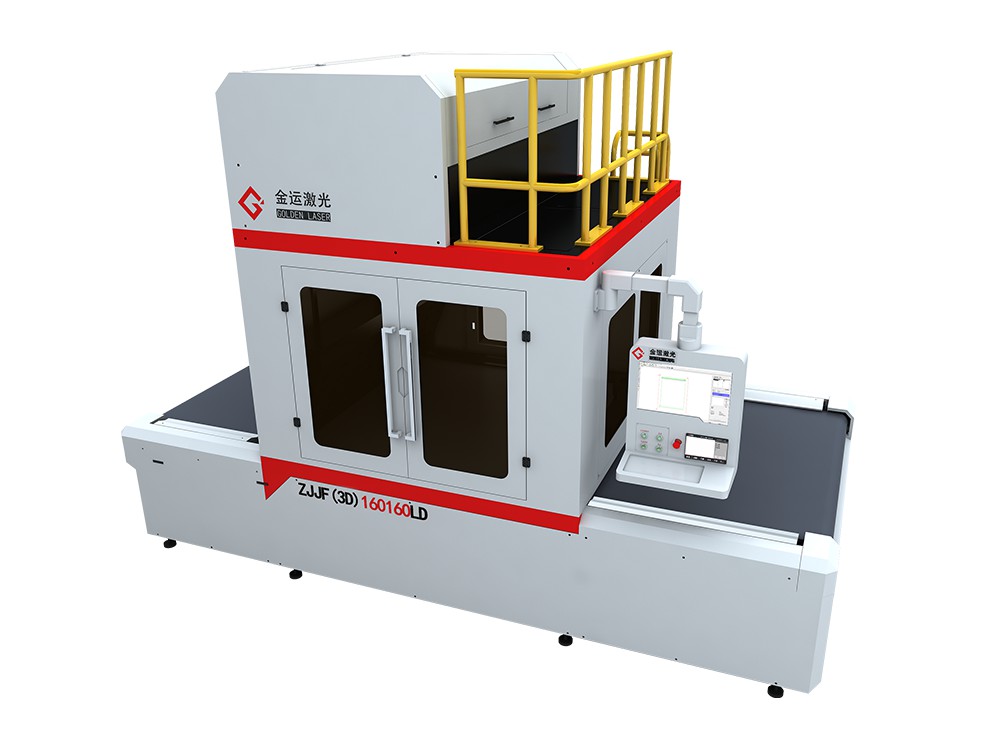

Vision Galvo Laser On-the-Fly Cutting Machine for Sublimation Fabric

Model No.: ZJJF(3D)-160160LD

Introduction:

Equipped with a galvanometer scanning system and a roll-to-roll working system, it can continuously process textiles with a maximum width up to 1600 mm.

The ‘Vision’ camera system scans the fabric, detects and recognize the printed shapes and thus cuts the selected designs quickly and accurately.

Roll feeding, scanning and cutting on-the-fly to achieve maximum productivity.

Galvo Laser Cutting On-the-Fly with Vision System

The fastest laser cutting of dye sublimation printed fabrics and textiles

Specifications

Main Technical Parameters of the ZJJF(3D)-160160LD Vision Galvo Laser Cutter

|

Laser type |

CO2 RF metal laser tube |

|

Laser power |

300W, 600W |

|

Working area |

1600mm×1000mm |

|

Working table |

Conveyor working table |

|

Motion system |

Offline Servo control system |

|

Cooling system |

Constant temperature water chiller |

|

Power supply |

AC380V±5%, 50Hz / 60Hz |

|

Graphic format supported |

AI, BMP, PLT, DXF, DST, etc. |

|

Standard configuration |

Roll to roll feeding and rewinding system, built-in control panel |

Watch Vision Laser in Action

Vision Scan On-the-fly Laser Cutting for Dye-sublimation Printed Sportswear and Masks

VISION LASER CUT - advanced laser cutting machine for dye sublimation, printed fabrics and textiles

High speed Galvo cutting on-the-fly, instant vectorisation, laser sealed edges. Just press and go!

Technical Parameter of the Vision Galvo Laser Cutter ZJJF(3D)-160160LD

|

Laser type |

CO2 RF metal laser tube |

|

Laser power |

300W, 600W |

|

Working area |

1600mm×1000mm |

|

Working table |

Conveyor working table |

|

Motion system |

Offline Servo control system |

|

Cooling system |

Constant temperature water chiller |

|

Power supply |

AC380V±5%, 50Hz / 60Hz |

|

Graphic format supported |

AI, BMP, PLT, DXF, DST, etc. |

|

Standard configuration |

Roll to roll feeding and rewinding system, built-in control panel |

GOLDENLASER Full Range of Vision Camera Laser Cutting Systems

Ultra High Speed Galvo Laser Cutting On-the-Fly Series

| Model No. | Working Area |

| ZJJF(3D)-160160LD | 1600mm×1600mm |

High Speed Scan On-the-Fly Cutting Series

| Model No. | Working area |

| CJGV-160130LD | 1600mm×1300mm (63”×51”) |

| CJGV-190130LD | 1900mm×1300mm (74.8”×51”) |

| CJGV-160200LD | 1600mm×2000mm (63”×78.7”) |

| CJGV-210200LD | 2100mm×2000mm (82.6”×78.7”) |

High Precision Cutting by Registration Marks

| Model No. | Working area |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

Ultra-Large Format Laser Cutting Series

| Model No. | Working area |

| ZDJMCJG-320400LD | 3200mm×4000mm (126”×157.4”) |

Smart Vision Laser Cutting Series

| Model No. | Working area |

| QZDMJG-160100LD | 1600mm×1000mm (63”×39.3”) |

| QZDXBJGHY-160120LDII | 1600mm×1200mm (63”×47.2”) |

CCD Camera Laser Cutting Series

| Model No. | Working area |

| ZDJG-9050 | 900mm×500mm (35.4”×19.6”) |

| ZDJG-3020LD | 300mm×200mm (11.8”×7.8”) |

Laser Cutting Sublimated Fabric Samples

Laser cutting sublimated apparel fabric with clean and sealed edges

Laser cutting hockey jerseys

Application

→ Sportswear Jerseys (basketball jersey, football jersey, baseball jersey, ice hockey jersey)

→ Cycling apparel

→ Active wear, leggings, yoga wear, dance wear

→ Swimwear, bikinis

Please contact goldenlaser for further information. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (laser marking) or laser perforating?

2. What material do you need to laser process? What is the size and thickness of the material?

3. What is your final product (application industry)?