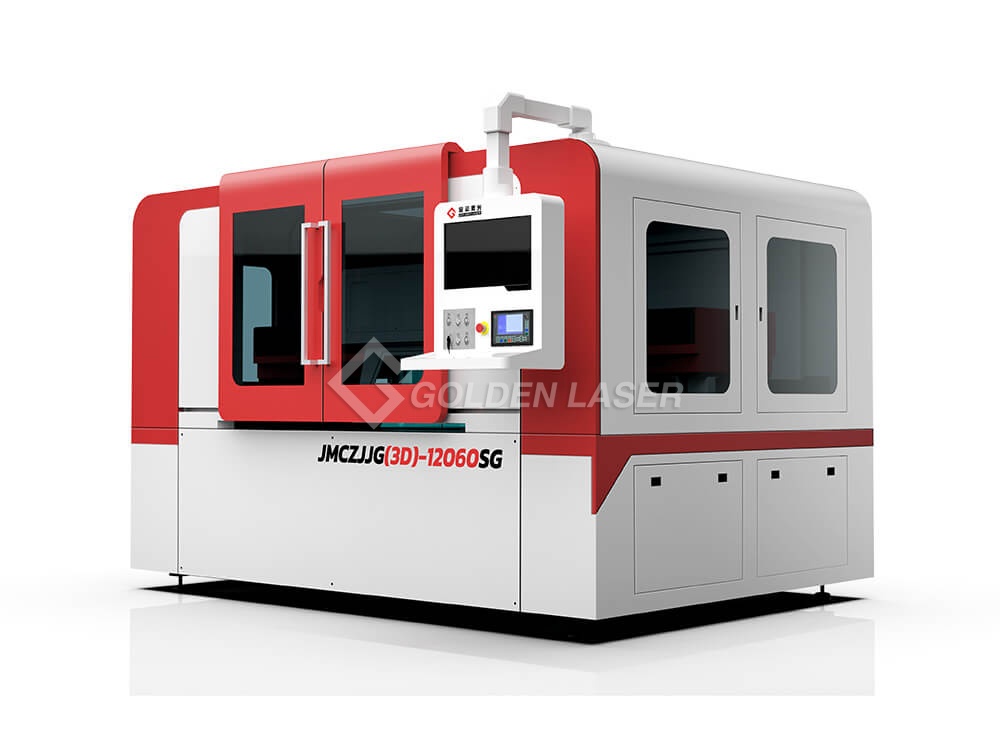

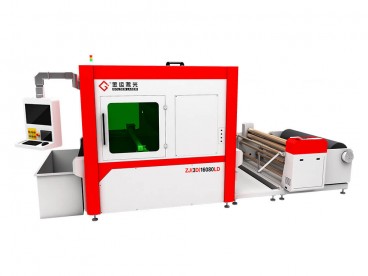

SuperLAB is a laser processing center for non-metal. It integrates laser marking, laser engraving and laser cutting functions. It can not only switch freely among multiple functions, but also has the functions of vision positioning, one key correction and auto focus, which is convenience and easy for use. It is a good helper for research & development and prototyping.

SuperLAB uses world-class optical components and high-quality optical modes to expand the processing range with high-speed and high-precision gantry. The galvanometric marking and X-Y gantry cutting share a set of laser source and can be switched at any time. A machine can fit a variety of requirements.

High cutting speed

Double gear rack driving system. Cutting speed 800mm/s. Acceleration: 8000mm/s2

Galvo and Gantry with CCD camera

X-Y laser cutting head and Galvo head automatically convert. Configured CCD camera simplify the working flow, saving time of multiple process alignment, reducing error caused by repeated positioning.

High cutting precision

Cutting precision is less than 0.2mm;

Mark point cutting error is less than 0.3mm

Improved precision of large format graphics splice

200mm format error is less than 0.2mm;

400mm format error is less than 0.3mm

New calibration automatic correction

Automatic calibration by camera, not need measure by hand. First time correction only takes 1~2 hours, easy to operate and less professional requirement for clients.

Automatic laser ranging system

No need repeat correction. Ranging system can automatically adjust distance between laser head and table according to different thickness of materials, ensuring laser focus in correct position.

Galvo head and X-Y cutting head switching

Dual core laser processing system

Follow-up focusing system

High precision camera recognition system

High speed & high precision cutting

3D dynamic large area engraving and perforating system

Galvo and gantry head with CCD camera

Precise cambered laser cutting tech

Automatic nesting

Continuous laser engraving with patterns splicing tech

Mark point locating cutting and joint recognition

Watch This Laser Machine in Action!

Technical Parameters

| Model No. |

ZDJMCZJJG-12060SG |

| Laser type |

CO2 RF metal laser tube |

| Laser power |

150W, 300W, 600W |

| Galvo system |

3D dynamic system, galvanometer SCANLAB laser head, scanning area 450mm×450mm |

| Working area |

1200mm×600mm |

| Working table |

Automatic up-down Zn-Fe honeycomb working table |

| Vision system |

CCD camera mark point recognize cutting |

| Motion system |

Servo motor |

| Maximum position speed |

Up to 8m/s |

| Cooling system |

Constant temperature water chiller |

| Model No. |

Products |

Working Areas |

| ZDJMCZJJG-12060SG |

Co2 Laser Cutter & Galvo Laser with CCD Camera |

1200mm×600mm (47.2in×23.6in) |

| ZJ(3D)-9045TB |

Galvo Laser Engraving Machine |

900mm×450mm (35.4in×17.7in) |

| ZJ(3D)-160100LD |

Galvo Laser Engraving Cutting Machine |

1600mm×1000mm (62.9in×39.3in) |

| ZJ(3D)-170200LD |

Galvo Laser Engraving Cutting Machine |

1700mm×2000mm (66.9in × 78.7in) |

| JMCZJJG(3D)210310 |

Flatbed CO2 Gantry and Galvo Laser Cutting Engraving Machine |

2100mm×3100mm (82.6in×122in) |

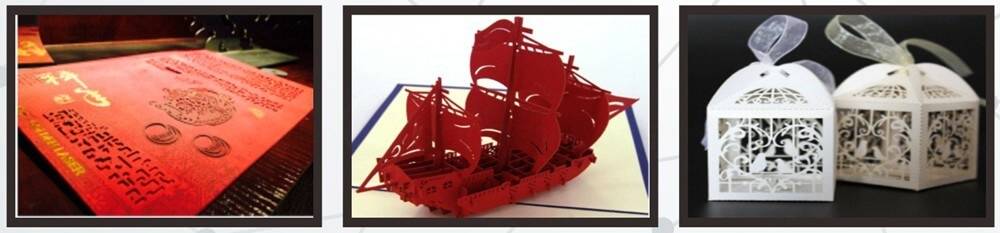

Application

• Small logo, twill letter, number and other precise items

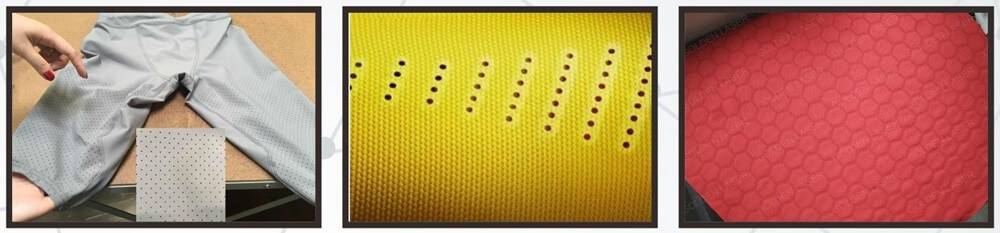

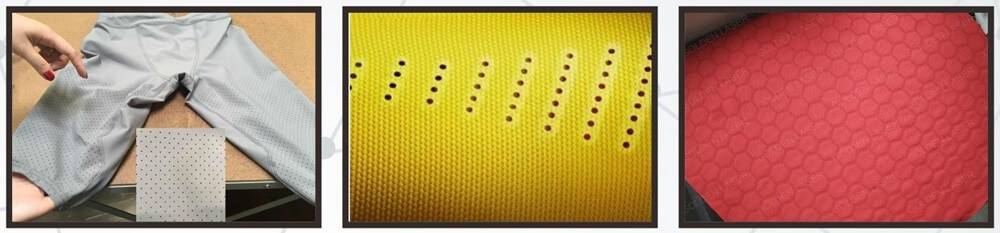

• Jersey perforating, cutting, kiss cutting; Active wear perforating; Jersey etching

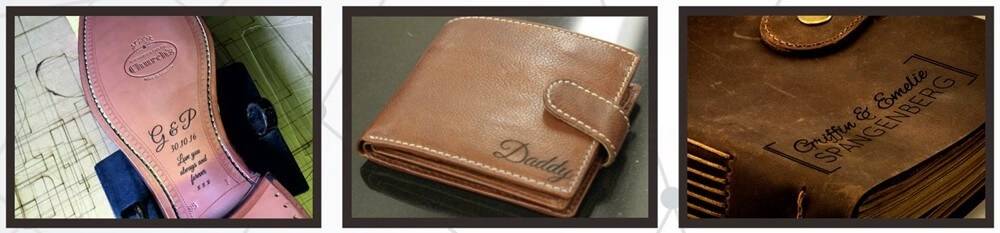

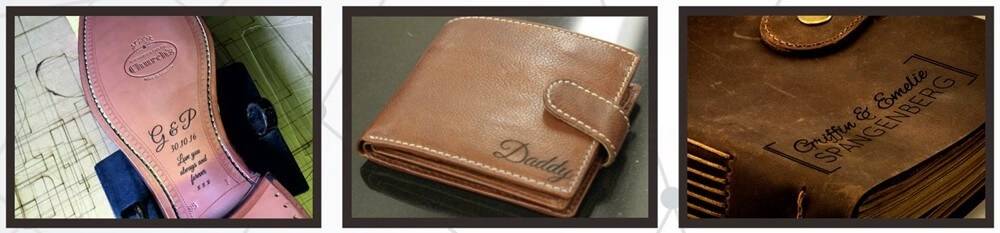

• Shoes, bags, suitcase, leather products, leather badges, leather crafts engraving

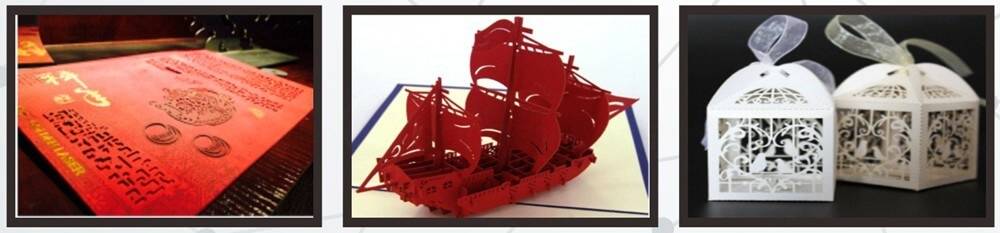

• Printing model board industry

• Greeting cards and delicate carton industry

• Suits for but not limited to fleece materials, denim, textile engraving

Please contact GOLDEN LASER for more infomation. Your response of following questions will help us recommend the most suitable machine.

1. What is your main processing requirement? Laser cutting or laser engraving (marking) or laser perforating?

2. What material do you need to laser process?

3. What is the size and thickness of the material?

4. After laser processed, what will be the material used for? (application) / What is your final product?

5. Your company name, website, Email, Tel (WhatsApp…)?