Ungathanda ukuthola izinketho eziningi nokutholakala kwezinhlelo ze-laser nezixazululo zezinqubo zebhizinisi lakho? Sicela ugcwalise leli fomu elingezansi. Ochwepheshe bethu bahlale bejabule ukukusiza futhi bazobuyela kuwe ngokushesha.

I-Laser Cutting ye-Kevlar ne-Aramid

I-Laser Processing Esebenzayo ye-Kevlar (Aramid) - Ukusika i-Laser

I-Kevlar kanye ne-aramid kunzima ukusika kusetshenziswa izindlela ezijwayelekile zomshini ngenxa yezindawo zazo ezishisayo nezamamishini. Ukusikwa kwe-Kevlar kanye ne-aramid ngezindlela ezijwayelekile kuholela kukhwalithi yomkhiqizo ongemuhle kanye nesidingo samandla esikhethekile esikhethekile sokusebenza ngomshini. Kodwa-ke, ukwenziwa kwe-laser kunezinzuzo ezinkulu kunezindlela ezijwayelekile ngenxa yokunemba nokucubungula ngokushesha.

Njengethuluzi lesimanje lokusika,umshini wokusika we-laserinikeza izinzuzo zomkhiqizo wokugcina wekhwalithi ephezulu, ukunemba kokusebenza kanye nezinga eliphezulu lokuguquguquka, okuholela ekwamukelweni okuhle kakhulu emikhakheni yendwangu kanye nezimboni.Ukusika ku-Kevlar nge-CO2I-laser cutter iyenzeka kakhulu.Ukusika i-laser akuthinteki futhi, ngokungafani nemibese noma izindwani, i-laser beam ihlale ibukhali futhi ayibuthuntu, ngaleyo ndlela iqinisekisa ikhwalithi yokusika engaguquki. Ukushisa okukhiqizwa i-laser ngesikhathi sokusikwa kwe-Kevlar kuvala imiphetho futhi kuqede ukonakala.

Izinzuzo zokusikwa kwe-Laser ye-Kevlar (Aramid)

I-Aramid, imininingwane ye-Kevlar kanye nobuchwepheshe bokusika i-laser obuhlobene

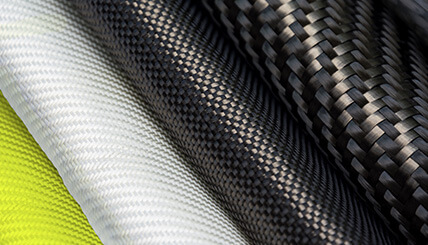

Isi-Aramid, okufushane nge-"aromatic polyamide", iyifayibha yokwenziwa eyenziwe umuntu esebenza kahle kakhulu. I-Aramid inezinto eziningi ezizuzisayo zemishini eziyenza ibe yinto ebaluleke kangaka emikhakheni eminingi ehlukene. Ngokuvamile isetshenziswa njenge-fiber reinforcement yezinhlanganisela ze-polymer matrix.I-Kevlarluhlobo lwefiber ye-aramid. Ilukwe ibe izinto zendwangu futhi iqine ngokwedlulele futhi ayisindi, imelana nokugqwala nokushisa. Isetshenziswa ezinhlelweni eziningi ezinjengobunjiniyela be-aerospace (njengomzimba wendiza), izivikelo zomzimba, amavesti angangenwa izinhlamvu, amabhuleki emoto, nezikebhe. Ngokuvamile kwenziwa izinhlanganisela. I-Kevlar ingabuye ihlanganiswe neminye imicu ukuze kukhiqizwe izinhlanganisela eziyingxube.

Ngenxa yamandla azo aphezulu kanye nokuqina kanye nemicu ijwayele ukufiphala, i-aramid ne-Kevlar kunzima ukubhola nokusika, kudinga idivayisi ekhethekile ukusika impahla.Ukusika i-Laseriyindlela enamandla futhi ephumelelayo yokucubungula izinhlanganisela eziningi.Umshini wokusika i-laseriyakwazi ukusika izinhlobo ezahlukene zezinto eziyinhlanganisela, okuhlanganisa i-aramid ne-Kevlar, okwenza kube nokwenzeka ukuhlinzeka ngezixazululo zomnotho ukuze uthole inzuzo esheshayo yemikhiqizo yekhwalithi ephezulu.