Ukusika kwe-metal laser, ubuhle bemboni obumangalisayo!

I-Metal laser processing, idinga kuphela ukuklama ihluzo kukhompyutha, ungenza ihluzo oyifunayo ngokushesha, ngezinzuzo zehluzo ezingenamkhawulo, usayizi nokujula okuguquguqukayo, ukunemba okuphezulu, okusheshayo, okubushelelezi futhi okungenayo i-burr, "akukho othintana naye" - akukho ukuchoboza impahla. Ukucutshungulwa kwe-laser sekuphenduke umsizi obalulekile embonini yokucubungula insimbi, futhi sekuzuze izinzuzo ezibalulekile zezomnotho nezenhlalo.

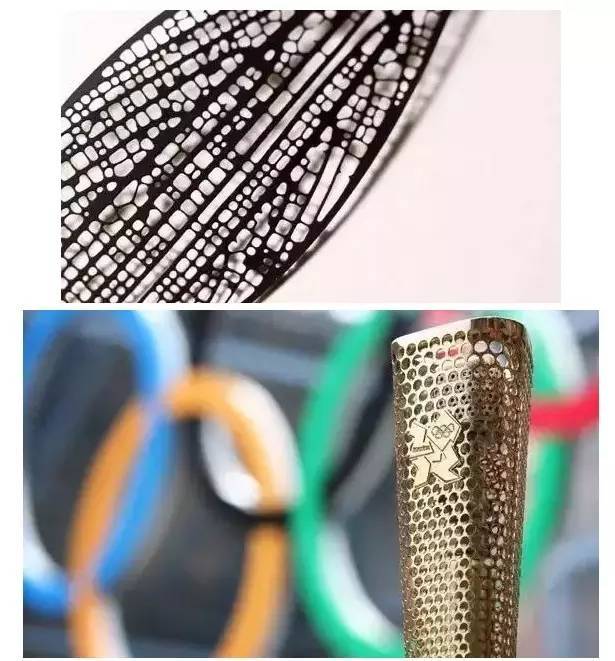

I-Laser Engraving

Ngokusekelwe kubuchwepheshe bokulawula be-CNC, nge-laser njengendawo yokucubungula, i-laser etching ezintweni, eshiya umkhondo omuhle.

Ukukhishwa kwe-laser

I-laser hollow iveza umuzwa wensimbi onezinhlangothi ezintathu kanye nesizotha, ukuze iveze ubuchwepheshe obuyingqayizivele kanye nokukhanga kobuciko.

Izicelo Zemboni

1. Isipho sobuciko

Ngenxa yokucubungula insimbi kanzima, ubuciko bensimbi obudlule bubiza kakhulu. Ukufika kwemishini ye-laser, akwenzi nje kuphela ukuthi ubuciko bensimbi buthuthukise ukusebenza kahle kokukhiqiza, ukunciphisa izindleko, futhi kwenze kube “amathoyizi” athengekayo.

2. Iminyango nokuhlobisa kweWindows

Izicabha zensimbi namafasitela zendabuko ziyabanda futhi zibuthuntu. Izakhi ze-laser zokusika imigodi zibe umhlobiso wezakhiwo, iminyango namafasitela ashintshashintsha njalo, anikeze umuzwa ojabulisayo.

3. Imihlobiso yokukhanyisa

Imigqa engenalutho ye-laser ebukekayo nenhle, ehlanganiswe namaphethini ejiyomethri asunguliwe endaweni ebiyelwe yensimbi elula, ukuze ukukhanya kwensimbi kuthole indawo yokuqala yobuhle.

4. Umbese

Ukumakwa kwe-laser kumathuluzi ommese wensimbi ukuze kutholakale ukuze kusetshenziswe nakho kungabongwa.