High Speed Industrial Textile Fabric Laser Tej Tshuab

Qauv No.: JMCCJG / JYCCJG Series

Taw qhia:

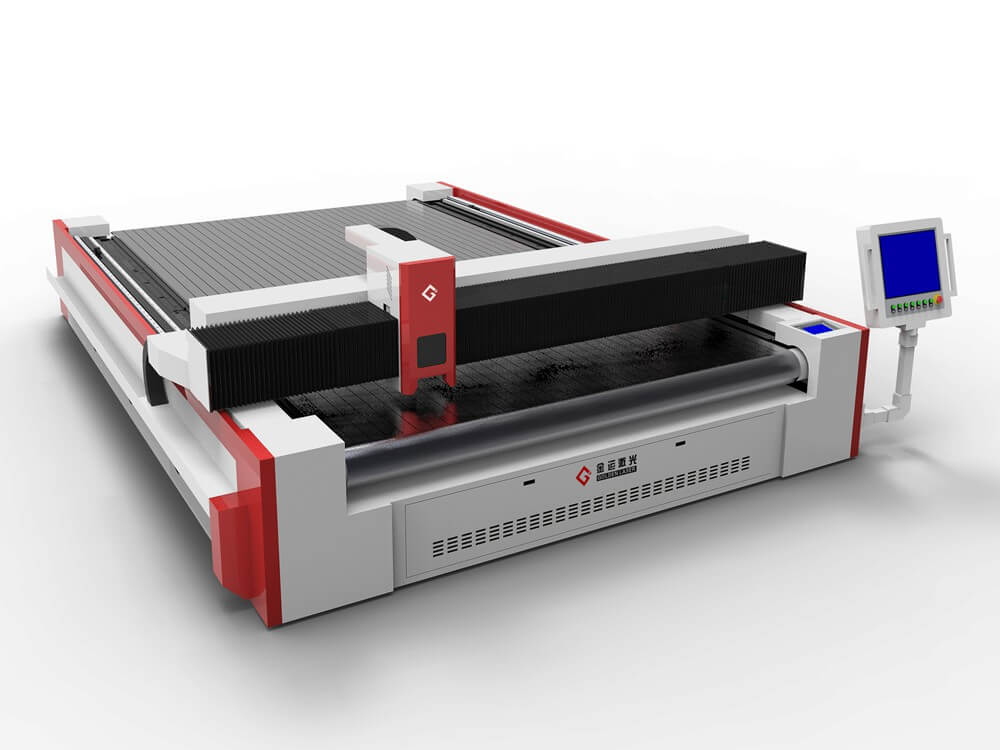

- No series CO2 flatbed laser txiav tshuab yog tsim los rau dav textile yob thiab cov ntaub ntawv mos txiav thiab txiav tsis tu ncua.

- Tsav los ntawm iav thiab khib nrog servo lub cev muaj zog, lub laser cutter muab lub siab tshaj plaws txiav ceev thiab acceleration.

- Cov pob software thiab cov kev xaiv ntxiv tuaj nrog lub laser txiav system yog muab los ua kom tiav cov digital thiab ntse ua.

Lub CO2 flatbed fabric laser cutter yog tsim los rau dav textile yob thiab cov ntaub ntawv mos txiav thiab txiav tsis tu ncua. Tsav los ntawmiav thiab khibnrogservo lub cev muaj zogtswj, lub laser txiav tshuab muab siab precision thiab txiav zoo ntawm lub siab tshaj plaws txiav ceev thiab acceleration. Lub tshuab laser cutter muaj nrog lub zog laser los ntawm 150 watt txog 800 watt. Covloj hom ntawv txiavtuaj yeem siv rau feem ntau ntawm cov ntaub ntawv yob.

Nrog kev xaiv ntawm lubauto-feeder, yob cov ntaub ntawv yog pub rau lub rooj txiav ncaj qha thiab txiav tsis tu ncua. Lub tshuab yog nrognqus tsev vacuumsub osconveyorlub rooj ua haujlwm, uas ua kom cov ntaub ntawv tiaj tus ntawm lub rooj. txawvpom kev systemstuaj yeem nruab nrog lub tshuab laser no rau ntau daim ntawv thov xws li dye sublimation luam ntawv textile txiav. Thiab kos cwj mem lossis ink-jet luam lub taub hau xaiv muaj los ua cov cim rau kev xaws lossis lwm lub hom phiaj.

Tshuab Nta

Nta ntawm High performance flatbed CO2 laser txiav tshuab

•Qhov nolaser txiav tshuabxaceev thiab tsis tshua muaj tseeb uaua tsaug rau nws cov khoom zoo.Muaj kev cia siab heev thiab kev saib xyuas dawb.

High precision qib iav thiab khib tsav tsheb.Nrog high-powered CO2 laser raj, txiav ceev txog 1,200mm / s, acceleration mus txog 8,000mm / s2, thiab tuaj yeem tswj tau lub sijhawm ntev.

Japanese Yaskawa servo lub cev muaj zog

- Ua kom muaj qhov siab tshaj plaws, kev ntseeg siab, thiab kev ua haujlwm.

•Qhov nolaser tshuablos nrogconveyor system. Lub tshuab pub cov khoom siv tau nyob rau hauv lub voj voog tsis tu ncua hauv synchronism nrog lub txaj conveyor tshem tawm lub sijhawm poob tag nrho kom ua tiav cov khoom tsim tau siab tshaj plaws.

Ntxiv rau, covnqus tsev conveyorworktable muaj kev ua haujlwm ntawmtsis zoo siab adsorptionlos xyuas kom meej qhov flatness ntawm cov ntaub thaum laser txiav.

• Tsis siv neeg feedernrogdeviation khomuaj nuj nqi (yeem) los xyuas kom meej kev pub mis.

• Qhov tshwj xeeb phau ntawv thiab tsis siv neeg sib tham sibnesting softwaremuaj nuj nqi tuaj yeem txhim kho cov ntaub siv rau qhov kawg.

• Nrog rautso pa system, lub taub hau laser thiab lub tso pa tawm synchronize; zoo tso tawm cov nyhuv, kom ntseeg tau tias plua plav tshuaj tsis ua paug cov ntaub ntawv.

• Nws muaj peev xwm ua kom tiavtag nrho cov hom ntawv txiav ntawm qhov ntxiv-ntev layoutnrog rau ib qho layout ntev uas tshaj cov ntawv txiav.

• Covlaser txiav system is modularhauv kev tsim raws li cov neeg siv khoom 'kev xav tau.

Ceev Specifications

| Laser hom | CO2 RF hlau laser |

| Laser zog | 150W 300W 600W 800W |

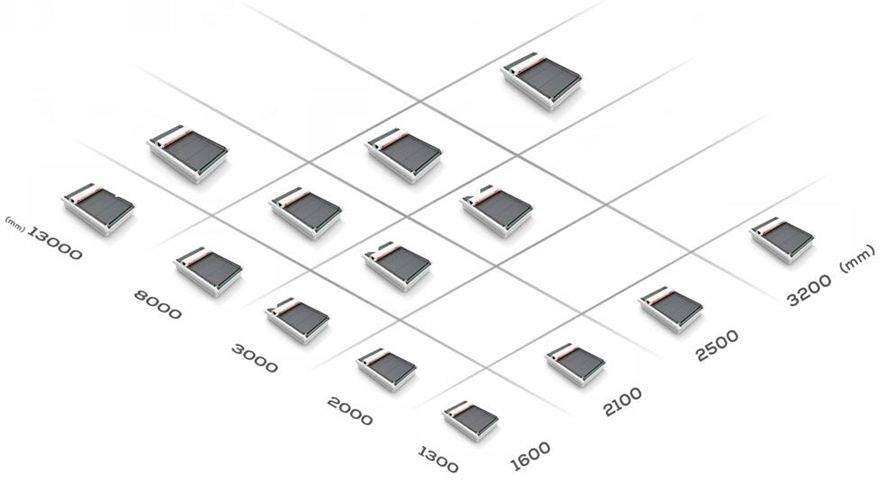

| Chaw ua haujlwm | 2000mm ~ 8000mm (L) × 1300mm ~ 3200mm (W) |

| Lub rooj ua haujlwm | Nqus conveyor ua hauj lwm rooj |

| Motion system | Khib thiab pinion kis tau tus mob, Servo lub cev muaj zog tsav |

| Txiav ceev | 0 ~ 1,200mm / s |

| Kev nrawm | 8,000mm / s2 |

| Laser hom | CO2 DC iav laser |

| Laser zog | 150W 300W |

| Chaw ua haujlwm | 2000mm ~ 8000mm (L) × 1300mm ~ 3200mm (W) |

| Lub rooj ua haujlwm | Nqus conveyor ua hauj lwm rooj |

| Motion system | Khib thiab pinion kis tau tus mob, Servo lub cev muaj zog tsav |

| Txiav ceev | 0 ~ 600mm / s |

| Kev nrawm | 6,000mm / s2 |

Laser Cut Processing Workflow

Yuav ua li cas Co2 laser txiav tshuab rau textile ua hauj lwm?

Qhov tseem ceeb ntawm Flatbed CO2 Laser Cutter

Kev xaiv ntxiv ua kom yooj yim rau kev tsim khoom thiab ua kom muaj peev xwm

Kev nyab xeeb tiv thaiv npog

Ua kom muaj kev nyab xeeb dua thiab txo cov pa taws thiab plua plav uas yuav raug tsim thaum lub sijhawm ua haujlwm.

Nws muaj nrogDaim Ntawv Pov Thawjkev xaiv kom tau raws li chav kawm 1 laser khoom kev tiv thaiv kev nyab xeeb.

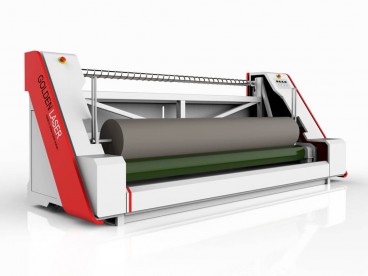

Nws pib Feeder

Nws yog ib chav pub noj uas khiav synchronous nrog lub laser cutter. tus feeder yuav hloov cov ntaub ntawv yob mus rau lub rooj txiav tom qab koj muab cov yob rau ntawm lub feeder. Koj tuaj yeem teem caij sib txawv pub noj raws li lub ntsiab tshuab ceev. Lub feeder muaj lub sensor los xyuas kom meej qhov chaw ntawm cov khoom. Lub feeder tuaj yeem nruab nrog qhov sib txawv ntawm qhov sib txawv rau cov yob sib txawv. Qhov sib txawv pneumatic cov menyuam yuav siv rau cov textiles nrog sib txawv nro, thickness... Chav tsev no yuav pab tau koj kom paub ib tug kiag li automated txiav txheej txheem.

Lub tshuab nqus tsev nqus tsev vacuum

Lub tshuab nqus tsev yog nyob rau hauv lub rooj txiav, muaj ib tug series ntawm qhov nyob rau saum npoo ntawm lub rooj rub cov khoom mus rau saum npoo. Lub tshuab nqus tsev tso cai rau tag nrho nkag mus rau saum npoo, tsis muaj dab tsi los ntawm txoj kev ntawm lub teeb laser thaum nws txiav. Nrog rau cov kiv cua muaj zog ua ke, nws kuj pab tiv thaiv cov pa taws thiab plua plav thaum txiav.

Vision System

Lub zeem muag qhov system yog qhov kev xaiv tseem ceeb thaum koj xav txiav cov contours. Tsis muaj teeb meem rau kev luam ntawv contour lossis paj ntaub contour, koj yuav xav tau cov cuab yeej no los nyeem cov contour lossis cov ntaub ntawv tshwj xeeb rau kev tso thiab txiav. Contour scanning thiab cim scanning yog haum rau ntau daim ntawv thov. Peb muab cov kev pom kev sib txawv rau cov kev siv sib txawv.

Kos Module

1. Mark cwj mem

Rau feem ntau ntawm cov laser txiav daim, tshwj xeeb tshaj yog rau textiles, nws yuav tsum tau sewn tom qab txiav. Koj tuaj yeem siv tus cwj mem los ua cov cim rau ntawm daim ntawv txiav los pab cov neeg ua haujlwm kom xaws tau yooj yim. Koj tuaj yeem siv tus cwj mem los ua qee cov cim tshwj xeeb ntawm cov khoom txiav xws li tus lej xov tooj ntawm cov khoom, qhov loj ntawm cov khoom, hnub tsim khoom thiab lwm yam ... Koj tuaj yeem xaiv cov xim sib txawv ntawm cov cwj mem raws li xim ntawm koj cov ntaub ntawv.

2. Ink-jet luam ntawv

Piv nrog rau "kos cwj mem" lub tshuab luam ntawv ink-jet luam ntawv yog txheej txheem tsis kov, yog li nws tuaj yeem siv rau ntau hom khoom sib txawv. Thiab muaj cov inks sib txawv rau ib qho kev xaiv xws li tus cwj mem tsis hloov pauv thiab tus cwj mem tsis hloov pauv, yog li koj tuaj yeem siv nws hauv kev lag luam sib txawv.

Liab Dot Pointer

- Laser Beam Tracing System

Qhov taw qhia liab dot pab raws li kev siv los txheeb xyuas qhov twg lub laser beam yuav tsaws rau koj cov khoom los ntawm kev taug qab ib qho kev simulation ntawm koj tus tsim yam tsis ua kom lub laser. Raws li koj qhov chaw pib.

Dual Lub taub hau

Basic ob lub taub hau laser

Ob lub laser taub hau yog mounted rau tib lub gantry, uas tso cai rau ob qho tib si qauv txiav ib txhij.

Independent dual lub taub hau

Kev ywj pheej dual lub taub hau tuaj yeem txiav cov qauv sib txawv tib lub sijhawm. Nws nce qhov kev ua tau zoo ntawm kev txiav thiab kev tsim khoom yooj yim ntawm qhov loj tshaj plaws.

GALVO Lub taub hau

Galvo laser siv high-ceev, tsav-tsav iav tsom iav los coj lub teeb laser los ntawm lub lens. Nyob ntawm txoj hauj lwm nyob rau hauv lub laser marking teb, lub beam cuam tshuam cov khoom ntawm ib tug ntau dua los yog tsawg lub kaum sab xis ntawm inclination. Qhov cim qhov loj me yog txhais los ntawm lub kaum sab xis deflection thiab qhov focal ntev ntawm optics. Txij li thaum tsis muaj qhov txav tau (nrog rau qhov tshwj xeeb ntawm daim iav) lub laser beam tuaj yeem coj mus rau qhov chaw ua haujlwm ntawm qhov nrawm nrawm nrog kev ua haujlwm siab thiab kev ntseeg siab, ua rau lawv zoo tagnrho thaum lub sijhawm luv luv thiab cov cim zoo yuav tsum tau.

Tsis siv neeg sorting System

Nce qib ntawm automation thaum lub sij hawm unloading thiab sorting txheej txheem kuj accelerates koj cov txheej txheem tsim tom ntej.

Cov txiaj ntsig ntawm textiles txiav nrog laser tshuab los ntawm goldenlaser

Ntxuav cov npoo - tsis muaj lint-dawb txiav

Lub laser tsis siv neeg kaw cov npoo txiav thiab yog li, tiv thaiv fraying. Piv nrog rau kev txiav tshuab, laser txiav txuag ntau cov kauj ruam ua haujlwm hauv kev ua haujlwm ntxiv.

Nruam txiav los ntawm yob

Laser txiav textiles thiab fabrics ncaj qha los ntawm yob ua tsaug rau lub conveyor system thiab tsis siv neeg feeder. Muaj peev xwm ntawm ultra-ntev format processing.

Laser txiav cov ntsiab lus zoo heev

Laser yog qhov tsim nyog rau kev txiav cov duab zoo kawg nkaus thiab cov qauv tsim, txawm tias txiav qhov me me (laser perforation).

Technical Parameters ntawm Laser Cutter Tshuab

| Cov qauv | JMCJG SERIES | JYCCJG SERIES |

| Laser hom | CO2 RF hlau laser | CO2 DC iav laser |

| Laser zog | 150W 300W 600W 800W | 150W 300W |

| Chaw ua haujlwm | 2000mm ~ 8000mm (L) × 1300mm ~ 3200mm (W) | |

| Lub rooj ua haujlwm | Nqus conveyor ua hauj lwm rooj | |

| Motion system | Khib thiab pinion kis tau tus mob, Servo lub cev muaj zog tsav | |

| Txiav ceev | 0 ~ 1,200mm / s | 0 ~ 600mm / s |

| Kev nrawm | 8,000mm / s2 | 6,000mm / s2 |

| Lubrication system | Tsis siv neeg lubrication system | |

| Fume extraction system | Cov yeeb nkab tshwj xeeb txuas nrog N centrifugal blowers | |

| Fais fab mov | AC380V ± 5% 50 / 60Hz 3phase / AC220V ± 5% 50 / 60Hz | |

| Graphic Format txaus siab | PLT, DXF, AI, DST, BMP | |

※ Lub rooj loj, laser zog thiab teeb tsa tuaj yeem kho raws li qhov xav tau.

GOLDENLASER - HIGH SPEED HIGH PreCISION CO2 Laser Cutter

Qhov chaw ua haujlwm: 1600mm × 2000mm (63 "× 79"), 1600mm × 3000mm (63 "× 118"), 2300mm × 2300mm (90.5 "× 90.5"), 2500mm × 3000mm (98.4 "× 1100mm), (118 "× 118"), 3500mm × 4000mm (137.7 "× 157.4"), thiab lwm yam.

*** Lub txaj qhov ntau thiab tsawg tuaj yeem kho raws li kev thov sib txawv.***

Cov ntaub ntawv siv tau

Polyester, nylon, nonwoven thiab woven fabrics, hluavtaws fibers, PES, polypropylene (PP), polyamide (PA), iav fiber (los yog iav fiber, fiberglass, fiberglass), Kevlar, aramid, Lycra, polyester PET, PTFE, ntawv, ua npuas ncauj, paj rwb, yas, viscose, felts, knitted fabrics, carbon fibers, 3Durar, fiber ntau sail ntaub, microfiber, spandex ntaub, thiab lwm yam.

Daim ntawv thov

1. Khaub ncaws Textile:fabrics thiab technical textiles rau kev siv khaub ncaws.

2. Tsev Textiles:ntaub pua plag, txaj, sofas, armchairs, curtains, cushion cov ntaub ntawv, hauv ncoo, pem teb thiab phab ntsa npog, textile wallpaper, thiab lwm yam.

3. Industrial Textiles:pom, cua dispersion ducts, thiab lwm yam.

4. Textiles siv nyob rau hauv automotive thiab aerospace:aircraft ntaub pua plag, miv lev, rooj zaum npog, rooj zaum siv, airbags, thiab lwm yam.

5. Sab nraum zoov thiab Sports Textiles:Cov khoom ua si, ya thiab sailing kev ua si, canvas npog, marquee tents, parachutes, paragliding, kitesurf, thiab lwm yam.

6. Tiv thaiv textiles:rwb thaiv tsev cov ntaub ntawv, mos mos vests, thiab lwm yam.

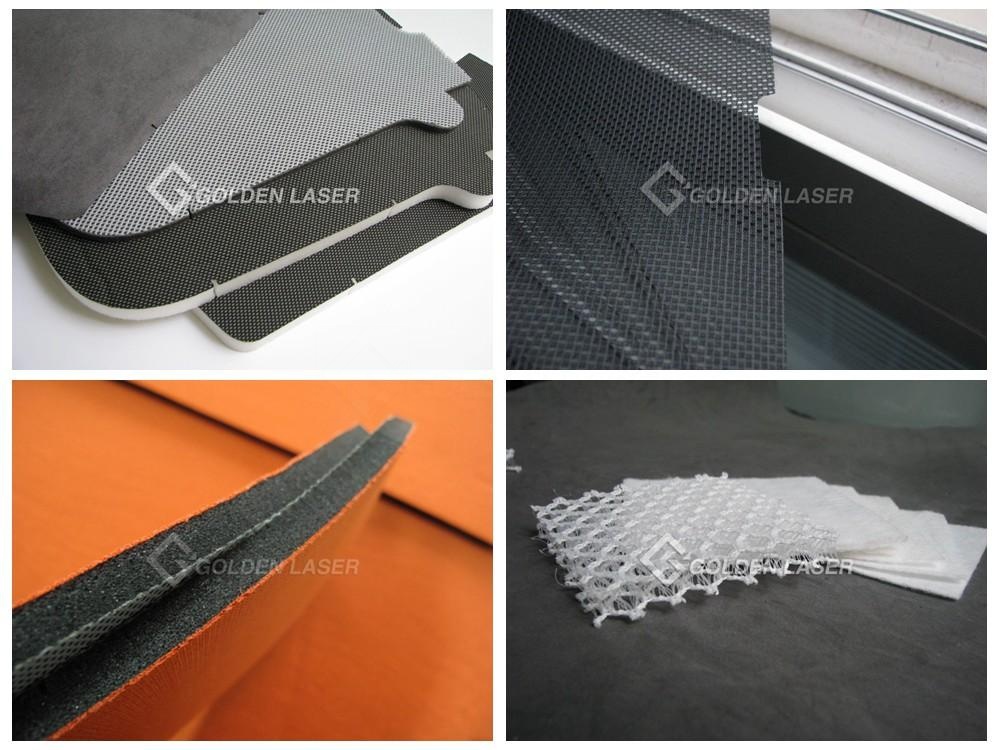

Textiles Laser Txiav Samples

<Nyeem ntxiv txog Laser Txiav thiab Engraving ntawm Textiles

Thov hu rau Golden Laser yog xav paub ntxiv. Koj cov lus teb ntawm cov lus nug hauv qab no yuav pab peb pom zoo rau lub tshuab tsim nyog tshaj plaws.

1. Koj qhov kev ua haujlwm tseem ceeb yog dab tsi? Laser txiav los yog laser engraving (laser marking) los yog laser perforating?

2. Cov khoom siv dab tsi koj xav tau rau txheej txheem laser?Qhov loj thiab thickness ntawm cov khoom yog dab tsi?

3. Koj qhov khoom kawg yog dab tsi(Application Industry)?