Galvo Laser Kulit Engraving Cutting Machine kanggo Industri Sepatu

Nomer Model: ZJ(3D)-160100LD

Pambuka:

- Laser engraving, perforating lan nglereni bisa rampung ing siji langkah.

- Sistem nyopir dual kanthi struktur rak gear.

- Sistem galvanometer sing dioptimalake.

- kacepetan Top lan Processing format Gedhe.

MANEH

Kacepetan dhuwur

Sistem nyopir rak gear pindho kacepetan dhuwur

Integrasi Galvo & Gantry

Cepet Galvo engraving lan format gedhe XY nglereni sumbu

Dhuwur Precision

Ukuran sinar laser sing tepat nganti 0.2mm

Multi-fungsi

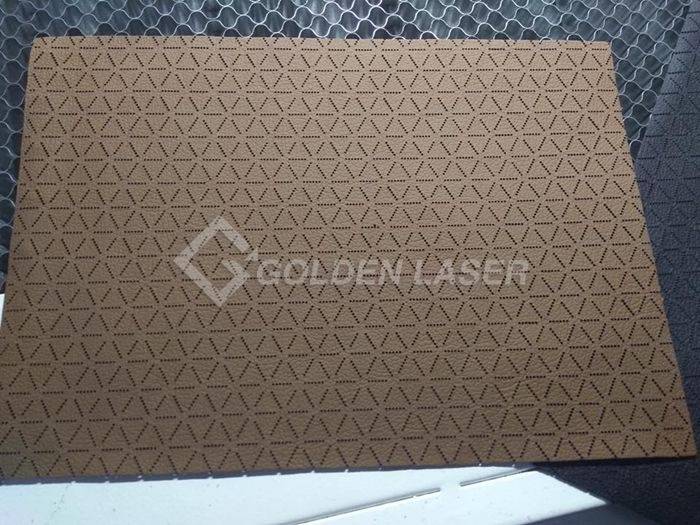

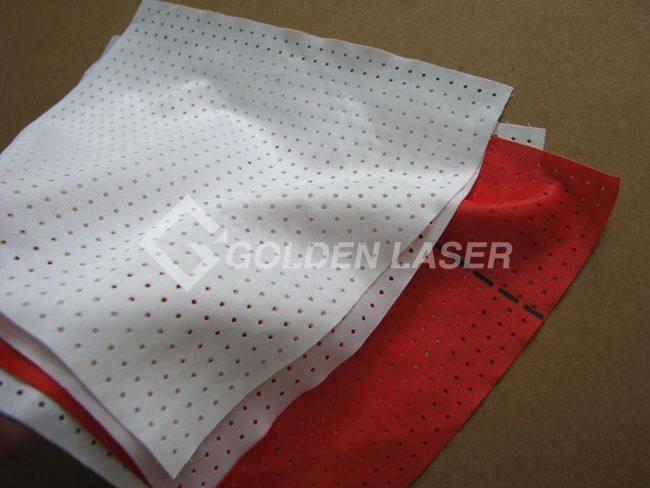

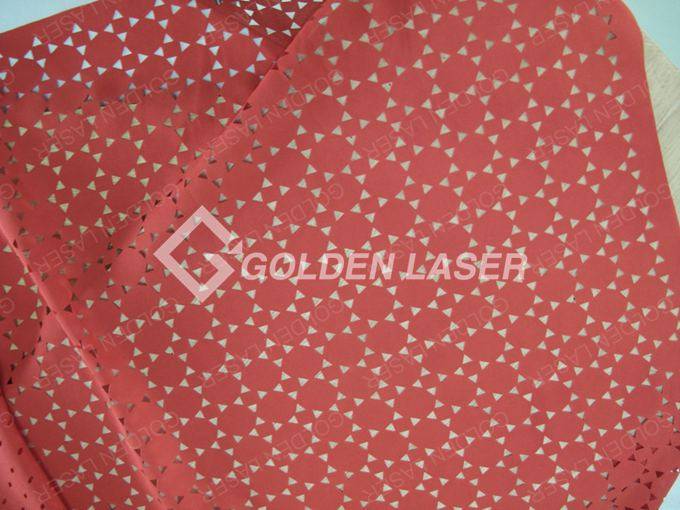

Engraving, perforating, hollowing, nglereni saka macem-macem kulit lan tekstil

Fleksibel

Ngolah desain apa wae. Ngirit biaya alat, ngirit biaya tenaga kerja lan ngirit bahan

Otomatis

Roll pangolahan laser otomatis kanggo muter thanks kanggo sistem conveyor lan feeder otomatis

Video Demo - Kepiye Cara Mesin Laser Galvo?

ENGRAVING LASER, nglereni lan perforating kulit langsung saka gulungan kanthi kacepetan dhuwur

Parameter teknis

| Model NO. | ZJ(3D)160100LD |

| jinis laser | CO2 RF logam tabung laser |

| Daya Laser | 150W / 300W / 600W |

| Sistem Galvo | Sistem dinamis 3D, kepala laser galvanometer, area pemindaian 450 × 450mm |

| Area kerja | 1600mm×1000mm (62.9in×39.3in) |

| Meja kerja | Zn-Fe honeycomb vakum conveyor desain meja kerja |

| Sistem gerak | Servo motor |

| sumber daya | AC220V±5% 50/60Hz |

| Konfigurasi standar | Pendingin banyu suhu konstan, Penggemar Exhaust, Kompresor udara |

| Konfigurasi opsional | Feeder otomatis, piranti filtrasi, bangunan sistem Exhaust |

※Penampilan lan spesifikasi bisa diganti amarga nganyari.

GOLDENLASER - Mesin Laser kanggo Ringkesan Industri Sepatu

| Produk | Jinis lan daya laser | Area kerja |

| XBJGHY160100LD Independent Dual Kepala Laser Cutting Machine | Laser kaca CO2 150W×2 | 1600mm×1000mm (62.9in×39.3in) |

| ZJ(3D)-9045TB Galvo Laser Engraving Machine | CO2 RF logam laser 150W / 300W / 600W | 900mm×450mm (35.4in×17.7in) |

| ZJ(3D)-160100LD Galvo Laser Engraving Cutting Machine | CO2 RF logam laser 150W / 300W / 600W | 1600mm×1000mm (62.9in×39.3in) |

| ZJ(3D)-170200LD Galvo Laser Engraving Cutting Machine | CO2 RF logam laser 150W / 300W / 600W | 1700mm×2000mm (66,9in × 78,7in) |

| CJG-160300LD / CJG-250300LD Kulit Asli Intelligent Nesting lan Sistem Pemotongan Laser | Laser kaca CO2 150W ~ 300W | 1600mm×3000mm (62.9in×118.1in) / 2500mm×3000mm (62.9in×98.4in) |

Integrasi multi-fungsi laser engraving, hollowing lan nglereni kulit lan kain saka gulungan.

Hubungi GOLDENLASER kanggo informasi luwih lengkap. Tanggepan sampeyan kanggo pitakonan ing ngisor iki bakal mbantu kita nyaranake mesin sing paling cocog.

1. Apa syarat pangolahan utama sampeyan? Laser nglereni utawa laser engraving (marking) utawa laser perforating?

2. Apa materi sampeyan kudu proses laser?

3. Apa ukuran lan kekandelan materi?

4. Sawise laser diproses, apa sing bakal digunakake kanggo materi? (industri aplikasi) / Apa produk pungkasan sampeyan?

Utawa sampeyan bakul utawa distributor kanggo mesin?