Sublimation Printed Fabric Laser Machine Goynta ee Dharka Jerseys Sports

Tusaalaha No.: CJGV-190130LD

Hordhac:

NIDAAMKA GOORINTA VISIONLASER – √ Quudinta tooska ah √ iskaanka duulista √ Xawaaraha sare √ ogaanshaha iyo garashada sariirta daabacan ee duub duuban. Goynta qalabyada kala duwan, sida polyester, cudbi, polymide, PVC, vinyl, iwm. Xawaaraha goynta laser wuxuu gaaraa ilaa 600 mm/s. Habka wax-soo-saarka otomaatiga ah ee leh suumanka gudbinta iyo nidaamka quudinta tooska ah.

Sublimation Mashiinka Goynta Maro Laser Daabacan

NIDAAMKA ARAGTIDA LAASERKA EE ARAGTIDA – √Quudinta tooska ah√Iskaanka duulista√Xawaaraha sare√Baadh (ogaanshaha iyo garashada) duub duuban oo dhar ah oo xisaabta ku dar wixii dhimis ah ama qalloocan taas oo dhici karta inta lagu jiro habka sublimation oo si sax ah u gooyay naqshad kasta.

Waa maxay sababta aragga laser-ka-goynta maro daabacan?

● Noocyo badanIska yaree agabyo kala duwan, sida polyester, cudbi, microfiber, polymide, PVC, vinyl, iwm.

● Xawaaraha Sare.Xawaaraha goynta laser wuxuu gaaraa ilaa 600 mm/s. Habka wax-soo-saarka otomaatiga ah oo leh gaadiid-qaade iyo hab-quudin toos ah.

● sax ahSaxnaanta sare, cidhifka goynta siman, jabin la'aan, looma baahna in dib loogu shaqeeyo geesaha jarista.

● NadiifiHabka laysarka ee aan xidhiidhka ahayn. Looma baahna in warqad lagu dhejiyo dunta, iyadoo laga fogaanayo wasakheynta gacanta inta lagu jiro habka goynta maqasyada.

● Dabacsanaan sare.Isku mar goo goo nooc kasta oo qaabab ah.

● Waqti badbaadi, kaydi alaabta, oo badbaadi kharashka shaqada.

Daabacaadda Dijitaalka ah Xalka Goynta Maro Laser Sublimation

●Aqoonsiga duulista qaab weyn. 5 ilbiriqsi si loo aqoonsado 1.6mx 3m. Marka quudinta suunka qaada, kamaradu waxay si dhakhso ah u aqoonsan kartaa dhar daabacan, ama xariijimaha, dharka plaids wakhtiga dhabta ah ka dibna macluumaadka goynta loo gudbiyo mashiinka goynta. Ka dib markii la gooyo qaab dhan, ka baaraandegidu waxay ku celin doontaa isla habka.

●Ku wanagsan la macaamilka sawirada kakan. Ku takhasusay habaynta walxaha laastikada. Cidhif nadiif ah, jilicsan, nadiif ah, cidhif toos ah, saxnaan sare.

●Hal mashiin ayaa farsamayn kara 500-800 oo dhar ah maalintii. Geedi socodka oo dhan iyada oo aan faragelin aadanaha. Nidaamka quudinta otomaatiga ah, soo saarista kontoorka sawirida, quudinta iyo goynta ayaa dhammaatay hal mar.

| Qaabka No. | CJGV-190130LD Aragtida Laser Cutter | |

| Nooca Laser | Co2 laser galaas | Co2 RF birta laser |

| Awoodda leysarka | 150W | 150W |

| Goobta shaqada | 1900mmX1300mm (74"×51") | |

| Shaxda Shaqada | Qaadista miiska shaqada | |

| Xawaaraha shaqada | 0-600 mm/s | |

| Meelaynta Saxnaanta | ±0.1mm | |

| Nidaamka Mooshinka | Nidaamka kontoroolka mootada ee servo-ka, shaashadda LCD | |

| Nidaamka qaboojinta | Qaboojiyaha heerkulka joogtada ah | |

| Bixinta Korontada | AC220V± 5% 50/60Hz | |

| Qaabka La Taageeray | AI, BMP, PLT, DXF, DST, iwm. | |

| Isku xirka caadiga ah | 1 qaybood oo taageere qiiqa sare ah 550W, 2 qaybood oo taageere qiiqa hoose ah 1100W, 2 kamaradaha Jarmalka | |

| Isku-xidhka Ikhtiyaarka | Nidaamka quudinta tooska ah | |

| Shuruudaha Deegaanka | Qiyaasta heerkulka: 10-35 ℃ Qiyaasta qoyaanka: 40-85% deegaanka la isticmaalo oo aan lahayn gubasho, qarax, magnet xoog leh, dhulgariir xoog leh | |

| ***Xusuusin: Sida badeecadaha si joogto ah loo cusboonaysiiyo, fadlannala soo xidhiidhtilmaamihii ugu dambeeyay.*** | ||

| LAASERKA DAHABKA AH - Mashiinka Goynta Laser Vision | Qaabka NO. | Goobta shaqada |

| CJGV-160130LD | 1600mm×1300mm (63" ×51") | |

| CJGV-160200LD | 1600mm×2000mm (63" ×78") | |

| CJGV-180130LD | 1800mm×1300mm (70" ×51") | |

| CJGV-190130LD | 1900mm×1300mm (74" ×51") | |

| CJGV-320400LD | 3200mm×4000mm (126" ×157") |

Codsiga

→ Dharka isboortiga ee Jerseys (maalinnada kubbadda kolayga, funaanadda kubbadda cagta, funaanadda baseball, funaanadda xeegada barafka)

→ Dharka baaskiilka

→ Xiro firfircoon, lug-goysyo, xirashada yoga, xirashada qoob ka ciyaarka

→ Dharka dabaasha, bikinis

1. Duqsiga - aqoonsiga qaab weyn oo goyn joogto ah

Hawshani waxa loogu talagalay maro qaabaysan oo si sax ah u meelaynta iyo goynta. Tusaale ahaan, iyada oo loo marayo daabacaadda dhijitaalka ah, sawiro kala duwan ayaa lagu daabacay dhar. Ka dib meelaynta iyo goynta, macluumaadka agabka ee ay soo saartayKamarada warshadaha xawaaraha sare leh (CCD), software aqoonsiga smart xiran garaafyada contour dibadda, ka dibna si toos ah u abuuraa jidka goynta iyo dhammayn jarista. Iyadoo aan loo baahnayn faragelinta bini'aadamka, waxay gaari kartaa goynta aqoonsiga joogtada ah ee dhammaan duubka daabacan. Tusaale ahaan habka weyn ee aqoonsiga muuqaalka, software-ku si toos ah ayuu u aqoonsanayaa qaabka kooraska ee dharka, ka dibna si toos ah u jarista garaafyada goynta, taas oo hubinaysa goynta saxda ah ee dharka.Faa'iidada ogaanshaha sambabada

- Looma baahna faylasha garaafyada asalka ah

- Si toos ah u ogow maryaha duuban ee duuban

- Si otomaatig ah oo aan gacanta lagu soo gelin

- Aqoonsiga 5 ilbiriqsi gudahood aagga goynta oo dhan

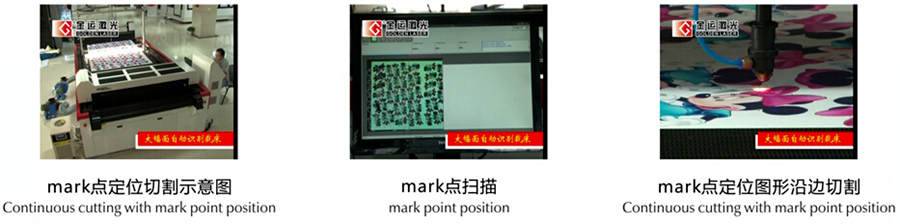

2. Goynta Calaamadaha Daabacan

Farsamadan goynta ayaa lagu dabaqi karaa qaabab kala duwan waxayna calaamadeeysaa goynta saxda ah. Gaar ahaan ku habboon daabacaadda joogtada ah ee jarista dharka goynta. Meelaynta barta calaamadeeyaha ma goynayso cabbirka qaabka ama xayiraadaha qaabka. Meelaynteedu waxay la xidhiidhaa laba dhibcood oo calaamade ah. Laba dhibcood ka dib si loo aqoonsado meesha, garaafyada qaabka oo dhan si sax ah ayaa loo jari karaa. (Fiiro gaar ah: Xeerarka habayntu waa inay isku mid ahaadaan qaab kasta oo garaafyada. Quudinta tooska ah ee goynta joogtada ah, si loogu qalabeeyo nidaamka quudinta.)Faa'iidada ogaanshaha calaamadaha daabacan

- Saxnimo sare

- Aan xadidnayn masaafada u dhaxaysa qaabka daabacan

- Aan xadidnayn daabacaadda naqshadeynta iyo midabka asalka

- Magdhawga habaynta walxaha

3. Xariijimaha iyo Goynta Plaids

Kamarada CCD, ee ku rakiban gadaasha sariirta goynta, waxay garan kartaa macluumaadka agabka sida xariijimaha ama saqafyada iyadoo loo eegayo kala duwanaanshaha midabka. Nidaamka buulku wuxuu samayn karaa buul toos ah iyadoo loo eegayo macluumaadka garaafyada ee la aqoonsaday iyo shuruudaha qaybo gooyay. Oo si toos ah ayuu u hagaajin karaa xagasha qaybaha si looga fogaado nabarrada ama falaxado qalloocan habka quudinta. Buul ka dib, mashruucu wuxuu soo dayn doonaa iftiin cas si uu u calaamadiyo xargaha goynta ee alaabta lagu hagaajinayo.

4. Goynta Square

Haddii aad u baahan tahay oo kaliya inaad gooyso labajibbaaran iyo leydi, haddii aadan haysan shuruud sare oo ku saabsan goynta saxda ah, waxaad dooran kartaa nidaamka hoose. Socodka shaqada: kamarad yar ayaa ogaata calaamadaha daabacaadda ka dibna laysarka ayaa gooyay afargeeska / leydiga.

<<Ka akhriso wax badan oo ku saabsan Xalka Goynta Laser Vision