Re mona ho u thusa ka likhetho tsa ho itlhophisa ho fihlela litlhoko tsa hau tse ikhethileng tsa tlhahiso.

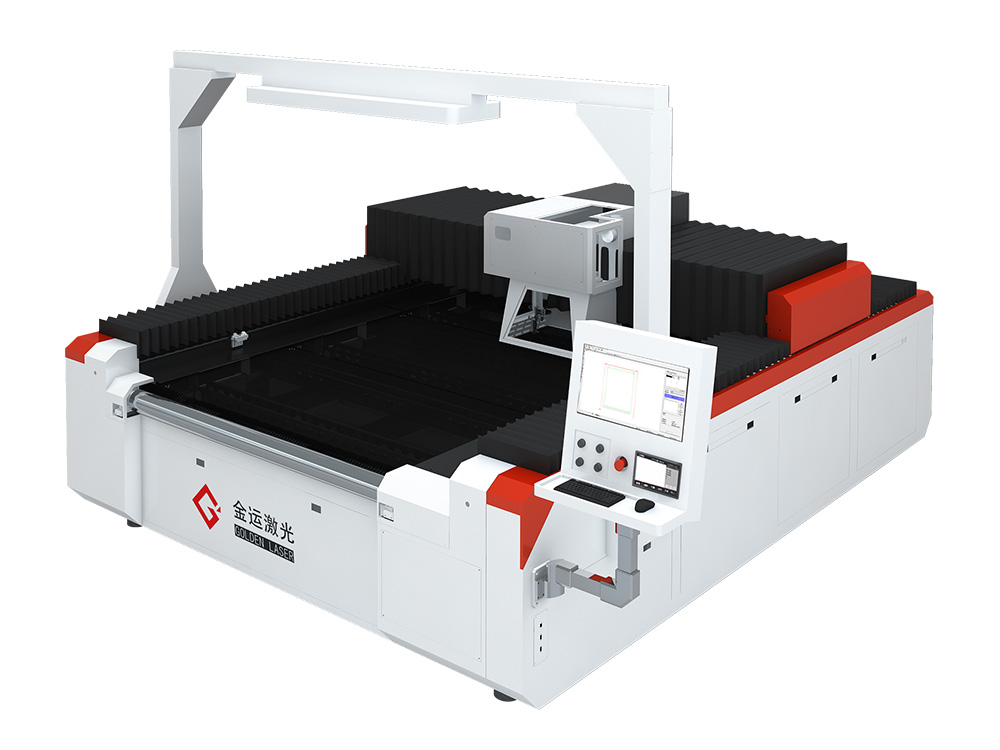

High Speed Laser Perforation le Mochini oa ho Seha o nang le Khamera

Nomoro ea mohlala: ZDJMCZJJG(3D)170200LD

Selelekela:

Sistimi ena ea ho itšeha ka laser e kopanya hantle ho nepahala ha Galvo le ho feto-fetoha ha maemo ha Gantry, e fana ka ts'ebetso ea lebelo le holimo bakeng sa mefuta e fapaneng ea lisebelisoa ha e ntse e ntlafatsa ts'ebeliso ea sebaka ka bokhoni ba eona ba mesebetsi e mengata.

Ho feta moo, ho ikamahanya le maemo ho hokahanya litsamaiso tse fapaneng tsa likhamera tsa pono ho lumella ho lemoha ka bohona ha li-contours le ho itšeha ka nepo bakeng sa lisebelisoa tse hatisitsoeng. Bokhoni bona bo ntlafatsa ts'ebetso le ho nepahala, haholo ts'ebelisong ea masela a feshene le a dijithale (dye-sublimation).

- Mokhoa oa ho sebetsa :1700mmx2000mm (e ka etsoa ka tlhokahalo)

- Matla a Laser:150W / 200W / 300W

- Pheta-pheta :±0.1mm

- Galvo lebelo:0-8000mm/s

- Lebelo la Gantry:0-800mm/s

- Khetho :Auto feeder

Lintlha-khōlō tsa Sebopeho sa Mochine

Moralo o kopaneng oa Galvo & Gantry o lumella mochini hore o fetohe ka mokhoa o se nang moeli lipakeng tsa litsamaiso tse peli tse fapaneng tsa taolo ea motsamao: sistimi ea galvanometer le sistimi ea gantry.

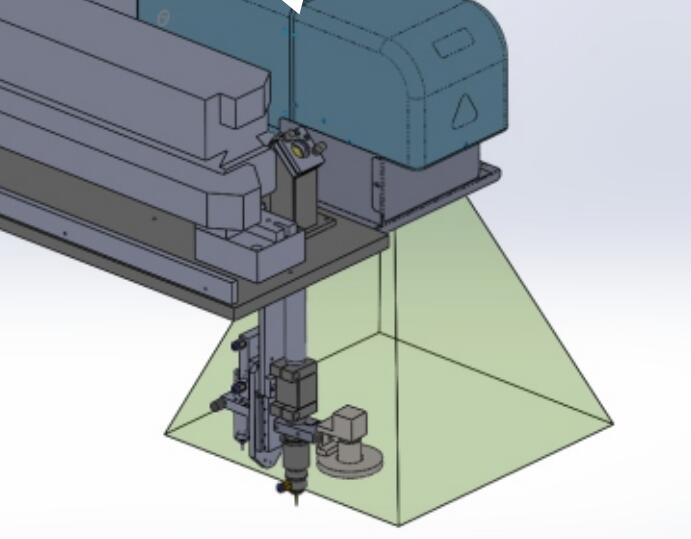

1. Sistimi ea Galvanometer:

Sistimi ea galvanometer e tsejoa ka lebelo le holimo le ho nepahala ha ho laola lebone la laser. E sebelisa sete ea liipone tse ka behang sebaka ka potlako ho tsamaisa lebone la laser ho potoloha bokaholimo ba thepa. Sistimi ena e sebetsa ka mokhoa o ikhethang bakeng sa mosebetsi o rarahaneng le o qaqileng, e fana ka metsamao e potlakileng le e nepahetseng ea laser bakeng sa mesebetsi e kang ho phunya le ho itšeha hantle.

2. Sisteme ea Gantry:

Ka lehlakoreng le leng, tsamaiso ea gantry e kenyelletsa mochine o moholo oa ho laola motsamao, oo hangata o nang le sebopeho sa gantry se nang le hlooho ea laser e tsamaeang. Sistimi ena e molemo bakeng sa ho koahela libaka tse kholoanyane 'me e loketse hantle lits'ebetso tse hlokang metsamao e pharaletseng, e fielang.

Mokhoa oa ho switjha o iketsang:

Bokhabane ba sebopeho sa ho fetoha ha othomathike ke bokhoni ba eona ba ho fetoha ka mokhoa o se nang moeli lipakeng tsa litsamaiso tsena tse peli ho ipapisitse le litlhoko tse ikhethileng tsa mosebetsi o haufi. Hangata tšobotsi ena e laoloa ke software 'me e ka hlophisoa ho kenya letsoho tsamaisong ea galvanometer bakeng sa lintlha tse rarahaneng, ebe o fetela tsamaisong ea gantry bakeng sa mesebetsi e pharaletseng, e fokolang, ntle le ho kenella ka letsoho.

Melemo:

- • Ho feto-fetoha ha maemo:Mochine o khona ho ikamahanya le mefuta e mengata ea lisebelisoa, ho tloha ho meralo e rarahaneng ho isa mesebetsing e meholoanyane ea ho itšeha.

- •Katleho e Atlehileng:Ho fetola ka mokhoa o itekanetseng ho netefatsa hore tsamaiso e nepahetseng ka ho fetisisa ea tsamaiso e sebelisoa bakeng sa karolo e 'ngoe le e' ngoe ea mosebetsi, ho eketsa katleho le ho fokotsa nako ea ho sebetsa.

- •Ho nepahala le lebelo:Ho kopanya matla a litsamaiso ka bobeli, tšobotsi ena e lumella ho leka-lekana ho lumellanang pakeng tsa ho nepahala le lebelo la ho sebetsa ka laser.

LIEKETSENG MOCHINA

Mochini oa Laser oa Golden Laser oa High-Speed Galvo & Gantry Laser - molekane oa hau ka ho nepahala le ka katleho.

Rack le Pinion Drive

Precision e kopana le lebelo ka sebopeho sa rona se matla sa rack le pinion drive, e netefatsang lebelo le holimo la li-synchronous tsa linaha tse peli bakeng sa lits'ebetso tse sebetsang hantle tsa ho roala le ho itšeha.

Sistimi ea 3D Dynamic Galvo

Eba le ho nepahala le ho feto-fetoha ha maemo ka sistimi ea rona ea taolo ea galvanometer e tsoetseng pele ea li-axis tse tharo, e fanang ka metsamao e nepahetseng ea laser bakeng sa liphetho tse holimo.

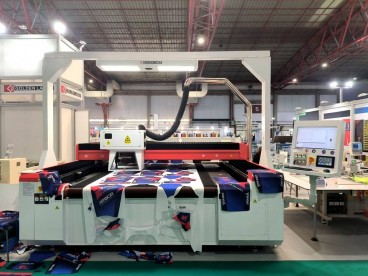

Sistimi ea khamera ea pono

Ho na le lik'hamera tsa morao-rao tse hlalosang boemo bo phahameng ba indasteri, mochine oa rona o tiisa tlhokomelo e tsoetseng pele ea pono le tlhophiso e nepahetseng ea thepa, e tiisang phetheho ho sehiloeng se seng le se seng.

Sistimi ea Taolo ea Motsamao

Ho rua molemo ho theknoloji e tsoetseng pele ea tsamaiso e koetsoeng e nang le litokelo tse ikemetseng tsa thepa ea mahlale, e netefatsang ts'ebetso e phahameng le ts'epo.

Sesebelisoa sa ho Latela Exhaust

Boloka sebaka sa hau sa mosebetsi se hloekile 'me se sebetsa hantle ka sesebelisoa sa rona sa morao-rao sa ho ntša metsi, ka potlako le ka mokhoa o hloekileng u tlose mosi mosebetsing oa ho itšeha.

Bethe e Matlafalitsoeng e Welded

Mochine ona o na le bethe e matlafalitsoeng e entsoeng ka tšepe le ho sila ka mokhoa o nepahetseng oa gantry, ho fana ka motheo o tsitsitseng bakeng sa ts'ebetso ea laser e nepahetseng le e ka tšeptjoang.

Kopo

Golden Laser's High-Speed Galvo & Gantry Laser Machine - E loketse mefuta e mengata ea liindasteri, ho kenyelletsa:

1. Liaparo le Liaparo tsa Lipapali:

E etselitsoe ka ho khetheha ho etsa masoba a moea le lipaterone tse rarahaneng liaparong tsa lipapali, liaparo tsa boikoetliso le li-leggings.

2. Liaparo, Feshene le Lisebelisoa:

E nepahetse bakeng sa ho seha ka mokhoa o nepahetseng le ho phunyeha ha lesela bakeng sa lintho tsa liaparo, ho etsa bonnete ba hore mahlakore a hloekileng le meralo e rarahaneng.

3. Letlalo le Lieta:

E loketse bakeng sa ho roala le ho seha letlalo le sebelisoang tlhahiso ea lieta le thepa e meng ea letlalo joaloka liatlana.

4. Lintho tsa Khabiso:

Ho itšeha ka mokhoa o nepahetseng bakeng sa ho theha mekhoa e rarahaneng linthong tse khabisitsoeng tse kang masela a tafole le likharetene.

5. Masela a Indasteri:

E loketse bakeng sa ho seha le masela a perforating a sebelisoang ka hare ho likoloi, masela a masela le masela a mang a tekheniki.

Ntlafatsa bokhoni ba hau ba tlhahiso ka High Speed Galvo & Gantry Laser Perforating and Cutting Machine ho tsoa ho Golden Laser.

Tekheniki Parameters

| Sebaka sa ho sebetsa | 1700mmx2000mm / 66.9"x78.7" (e ka etsoa ha ho hlokahala) |

| Tafole ea ho sebetsa | Tafole ea ho sebetsa ea conveyor |

| Matla a laser | 150W / 200W / 300W |

| Laser tube | CO2 RF tšepe laser tube |

| Sisteme ea ho khaola | XY gantry cutting |

| Perforation/mokgwa wa ho tshwaya | Sistimi ea GALVO |

| Sistimi e tsamaeang ea X-axis | Sistimi ea ho tsamaisa li-gear le rack |

| Sistimi e tsamaeang ea Y-axis | Sistimi ea ho tsamaisa li-gear le rack |

| Sistimi ea ho pholisa | Mocheso o tsitsitseng oa metsi a batang |

| Sistimi ea ho felloa ke matla | 3KW exhaust fan x 2, 550W exhaust fan x 1 |

| Phepelo ea motlakase | AC220V ± 5%, 50Hz/60Hz |

| Software | Khauta Laser ho tšoaea le ho itšeha Software |

| Ho sebetsa sebakeng | 3993mm(L) x 3550mm(W) x 1600mm(H) / 13.1' x 11.6' x 5.2' |

| Dikgetho tse ding | Auto feeder, letheba le lefubelu |

***Tlhokomeliso: Ka kopo, kaha lihlahisoa li lula li nchafatsoaiteanye le ronabakeng sa lintlha tsa morao-rao.***

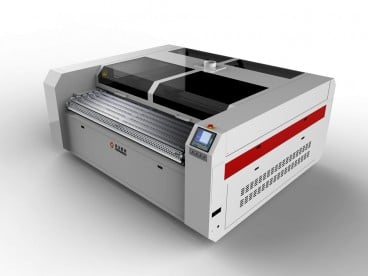

GOLDENLASER Full Range of Sublimation Laser Cutting Systems

① Mochini oa ho Seha Laser oa Vision Scanning

| Mohlala No. | Sebaka sa ho sebetsa |

| CJGV-160130LD | 1600mm×1200mm (63”×47.2”) |

| CJGV-190130LD | 1900mm×1300mm (74.8”×51”) |

| CJGV-160200LD | 1600mm×2000mm (63”×78.7”) |

| CJGV-210200LD | 2100mm×2000mm (82.6”×78.7”) |

② Mochini o Sehang oa Laser o Lemohileng Khamera (GoldenCam)

| Mohlala No. | Sebaka sa ho sebetsa |

| MZDJG-160100LD | 1600mm×1000mm (63”×39.3”) |

③ Smart Vision Laser Cutting Machine

| Mohlala No. | Sebaka sa ho sebetsa |

| QZDXBJGHY-160120LDII | 1600mm×1200mm (63”×47.2”) |

| QZDXBJGHY-180100LDII | 1800mm×1000mm (70.8”×39.3”) |

④ Galvanometer Flying Vision Laser Cutting Machine

| Mohlala No. | Sebaka sa ho sebetsa |

| ZJJF(3D)-160160LD | 1600mm×1600mm (63”×63”) |

⑤ Large Format Vision Laser Cutting Machine bakeng sa Papatso Libanner le Lifolakha

| Mohlala No. | Sebaka sa ho sebetsa |

| CJGV-320400LD | 3200mmx4000mm (10.5 ftx13.1ft) |

⑥ High Speed Perforation le Mochini o Sehang oa Laser o nang le Vision System

| Mohlala No. | Sebaka sa ho sebetsa |

| ZDJMCZJJG(3D)170200LD | 1700mmx2000mm (66.9"x78.7") |

Mochini oa High Speed Galvo & Gantry Laser Perforating and Cutting Machine o nang le Khamera e tsoang ho Golden Laser o sebetsa ka mefuta-futa 'me o ka sebelisoa mefuteng e mengata ea thepa. Mona ke lisebelisoa tse ikhethileng tseo mochini o ka li sebetsang hantle:

1. Liaparo tsa lipapali le tsa Activewear:

Masela a tekheniki, lisebelisoa tsa ho thella mongobo, le masela a otlohang a sebelisoang hangata ho liaparo tsa lipapali, liaparo tse sebetsang le leggings.

2. Masela a Liaparo:

Cotton, polyester, silika, nylon, spandex, le lisebelisoa tse ling tsa masela tse sebelisoang ha ho etsoa liaparo.

3. Lisebelisoa tsa Letlalo:

Letlalo la 'nete, letlalo la maiketsetso, le li-suede bakeng sa lits'ebetso tse fapaneng indastering ea feshene le ea lieta.

4. Lintho tsa Mokhabiso oa Lehae la Textile:

Masela a lituku tsa hlooho, masela a litafole, likharetene, le masela a mang a khabisitsoeng a sebelisoang thepa ea lapeng.

5. Masela a Indasteri:

Masela a ka hare a likoloi, likotopo tsa masela, le lisebelisoa tse ling tse boima tse sebelisoang lits'ebetsong tsa indasteri.

Ke habohlokoa ho hlokomela hore ho nepahala le ho feto-fetoha ha mochine ho etsa hore o tšoanelehe bakeng sa mefuta e mengata ea lisebelisoa ka har'a lihlopha tsena. Ntle le moo, bokhoni ba ho theha lipaterone tse rarahaneng le li-perforations li ntlafatsa likhetho tsa ho itlhophisa bakeng sa liindasteri tse fapaneng. Haeba u na le lisebelisoa tse ikhethileng bakeng sa kopo ea hau, mochini o ka li amohela, ha feela li oela ka har'a sebopeho se boletsoeng sa ts'ebetso le bokhoni ba botenya.