Mochini oa ho Seha oa Laser o Hatisitsoeng oa Sublimation bakeng sa Liaparo tsa Lipapali tsa Jerseys

Nomoro ea mohlala: CJGV-190130LD

Selelekela:

VISIONLASER CUTTING SYSTEM – √ Auto feeding √ Flying scan √ High lebelo √ Ho lemoha le ho lemoha moqhaka o hatisitsweng wa roll sublimated ya lesela. Ho khaola lisebelisoa tse sa tšoaneng, tse kang polyester, k'hothone, polymide, PVC, vinyl, joalo-joalo Lebelo la ho itšeha ka laser le fihla ho 600 mm / s. Ts'ebetso ea tlhahiso e ikemetseng e nang le mabanta a conveyor le sistimi ea ho fepa ka bo eona.

Mochini oa ho Seha oa Laser o hatisitsoeng ka Sublimation

PONO LASER SEHA SYSTEM – √Ho fepa ka boiketsetso√Sekene sa sefofane√Lebelo le phahameng√Skena (ho lemoha le ho lemoha) lesela le nang le sublimated ea lesela 'me u nahanele ho honyela kapa ho khopama hofe kapa hofe. e ka 'nang ea etsahala nakong ea ts'ebetso ea sublimation le ho khaola ka nepo meralo leha e le efe.

Hobaneng ha Vision Laser Cutting Printed Fabric?

● E fapaneng.Seha lisebelisoa tse fapaneng, joalo ka polyester, k'hothone, microfiber, polymide, PVC, vinyl, jj.

● Lebelo le phahameng.Lebelo la ho itšeha ka laser le fihla ho 600 mm / s. Mokhoa oa tlhahiso o ikemetseng o nang le conveyor le auto-feeding system.

● Nepahetseng.Ho nepahala ho phahameng, ho itšeha ka mokhoa o boreleli, ha ho na fraying, ha ho na tlhoko ea ho sebetsa ka mats'oafo.

● Hloekileng.Mokhoa o sa amaneng le laser. Ha ho hlokahale hore u khomarele pampiri holim'a masela, ho qoba tšilafalo ea matsoho nakong ea ho seha lisekere.

● Ho tenyetseha ho phahameng.Seha mefuta efe kapa efe ea libopeho ka nako e le 'ngoe.

● Boloka nako, boloka thepa, le ho boloka litšenyehelo tsa basebetsi.

Digital Printing Sublimation Fabric Laser Cutting Solution

●Tsebo e kholo ea ho fofa. Metsotsoana e 5 ho tseba 1.6mx 3m. Ha o fepa lebanta la conveyor, kh'amera e ka tseba kapele lesela le hatisitsoeng, kapa mela, lesela la plaids ka nako ea nnete ebe tlhaiso-leseling e fetisetsoang mochining oa ho itšeha. Kamora ho khaola sebopeho kaofela, ts'ebetso e tla pheta ts'ebetso e ts'oanang.

●E ntle ho sebetsana le litšoantšo tse rarahaneng. E sebetsana ka ho khetheha le lisebelisoa tsa elastic. E hloekile, e bonolo, e hloekile, moeli oa ho tiisa o ikemetseng, ho nepahala ho phahameng.

●Mochini o le mong o ka sebetsana le lihlopha tse 500-800 tsa liaparo ka letsatsi. Ts'ebetso eohle ntle le ho kenella ha motho. Ka sistimi ea ho fepa ka boits'oaro, ho qotlisoa ha li-contour, ho fepa le ho seha ho felile ka nako e le 'ngoe.

| Mohlala No. | CJGV-190130LD Vision Laser Cutter | |

| Mofuta oa Laser | Co2 laser laser | Co2 RF tšepe laser |

| Matla a Laser | 150W | 150W |

| Sebaka sa Mosebetsi | 1900mmX1300mm (74"×51") | |

| Tafole ea Mosebetsi | Tafole ea ho sebetsa ea conveyor | |

| Lebelo la ho Sebetsa | 0-600 limilimithara/s | |

| Boemo bo Nepahetseng | ±0.1mm | |

| Sistimi ea Motion | Sistimi ea taolo ea enjene ea servo, skrineng sa LCD | |

| Mokhoa oa ho Pholisa | Mocheso o tsitsitseng oa metsi a batang | |

| Phepelo ea motlakase | AC220V±5% 50/60Hz | |

| Sebopeho se tšehelitsoe | AI, BMP, PLT, DXF, DST, joalo-joalo. | |

| Kabo e Tloaelehileng | Li-sete tse 1 tsa fan ea ho qeta ka holimo ea 550W, lihlopha tse 2 tsa li-fan exhaust tse tlase 1100W, 2 Lik'hamera tsa Jeremane | |

| Kabo ea Boikhethelo | Mokhoa o itekanetseng oa ho fepa | |

| Tlhokahalo ea Tikoloho | Sebaka sa Mocheso: 10—35℃ Boemo ba mongobo: 40-85% tikoloho ea ts'ebeliso ea tšisinyeho ea lefatše e sa cheng, e phatlohang, e matla ea makenete, e matla | |

| ***Tlhokomeliso: Ka kopo, kaha lihlahisoa li lula li nchafatsoaiteanye le ronabakeng sa lintlha tsa morao-rao.*** | ||

| KHAUTA LASER - Vision Laser Cutting Machine | Mohlala NO. | Sebaka sa Mosebetsi |

| CJGV-160130LD | 1600mm×1300mm (63”×51”) | |

| CJGV-160200LD | 1600mm×2000mm (63”×78”) | |

| CJGV-180130LD | 1800mm×1300mm (70”×51”) | |

| CJGV-190130LD | 1900mm×1300mm (74”×51”) | |

| CJGV-320400LD | 3200mm×4000mm (126”×157”) |

Kopo

→ Liaparo tsa lipapali (lijesi tsa basketball, jeresi ea bolo ea maoto, jeresi ea baseball, jeresi ea leqhoa la hockey)

→ Liaparo tsa ho palama baesekele

→ Liaparo tse sebetsang, leggings, liaparo tsa yoga, moaparo oa tantši

→ Liaparo tsa ho sesa, li-bikini

1. Ho fofa - ho lemoha sebopeho se seholo ho tsoela pele ho itšeha

Mosebetsi ona ke oa lesela le entsoeng ka mokhoa o nepahetseng hantle le ho itšeha. Ka mohlala, ka khatiso ea digital, litšoantšo tse fapa-fapaneng tse hatisitsoeng holim'a lesela. Ka mor'a ho beha boemo le ho itšeha, boitsebiso bo ntšitsoeng ke bakh'amera ea indasteri ea lebelo le holimo (CCD), software smart identification e koetse litšoantšo tsa ka ntle tsa contour, ebe e iketsetsa tsela ea ho itšeha le ho qeta ho itšeha. Ntle le tlhokahalo ea ho kenella ha batho, e ka finyella ho itšeha ho tsoelang pele ha masela a hatisitsoeng a moqolo. Ke hore, ka mokhoa o moholo oa ho lemoha pono, software ka boeona e lemoha mokhoa oa contour oa seaparo, ebe o iketsetsa litšoantšo tsa ho itšeha, kahoo e netefatsa ho itšeha ho nepahetseng ha lesela.Molemo oa ho lemoha li-contour

- Ha ho hlokahale lifaele tsa litšoantšo tsa mantlha

- Ka ho toba lemoha moqolo hatisitsoeng masela

- Ka ho iketsa ntle le ho kenella ka letsoho

- Ho khetholla nakong ea metsotsoana e 5 sebakeng sohle sa ho itšeha

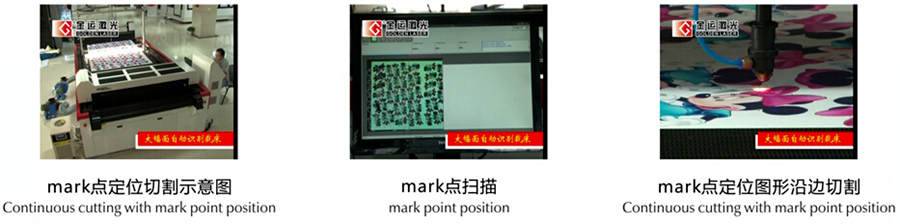

2. Printed Marks Cutting

Theknoloji ena ea ho itšeha e sebetsa mefuteng e fapaneng ea mekhoa le ho ngola ka mokhoa o nepahetseng oa ho itšeha. Haholo-holo a loketse bakeng sa jarolla ka ho iketsa e tsoelang pele ea khatiso liaparo contour seha. Sebaka sa ho beha lesupa ha se na boholo ba paterone kapa lithibelo tsa sebopeho. Boemo ba eona bo amana feela le lintlha tse peli tsa Marker. Kamora lintlha tse peli tsa Letšoao ho khetholla sebaka, litšoantšo tsohle tsa sebopeho li ka khaoloa hantle. (Tlhokomeliso: melao ea tlhophiso e tlameha ho tšoana bakeng sa mokhoa o mong le o mong oa setšoantšo. Ho fepa ka mokhoa o tsoelang pele, ho ba le lisebelisoa tsa ho fepa.)Molemo oa ho lemoha matšoao a hatisitsoeng

- Ho nepahala ho phahameng

- E sa lekanyetsoang bakeng sa sebaka se pakeng tsa paterone e hatisitsoeng

- E sa lekanyetsoang bakeng sa moralo oa khatiso le 'mala oa bokamorao

- Matšeliso a deformation ea thepa ea ho sebetsa

3. Ho Seha Lithapa le Lithako

Khamera ea CCD, e kentsoeng ka morao ho bethe ea ho itšeha, e khona ho lemoha tlhahisoleseding ea thepa e kang metsero kapa li-plaids ho latela phapang ea mebala. Sistimi ea ho haha sehlaha e ka etsa sehlaha sa othomathike ho latela tlhaiso-leseling e bonts'itsoeng le ho seha likotoana tse hlokahalang. 'Me e ka khona ho fetola likotoana ka bo eona ho qoba mela kapa li-plaids tse sothehileng ts'ebetsong ea ho fepa. Ka mor'a ho aha sehlaha, projekiti e ne e ntša lebone le lefubelu ho tšoaea mela e sehang linthong tsa ho lekanya.

4. Ho Seha Sekwere

Haeba o hloka feela ho seha lisekoere le kgutlonne, haeba o sena tlhokeho e phahameng mabapi le ho seha ka nepo, o ka khetha sistimi e ka tlase. Phallo ea mosebetsi: k'hamera e nyane e lemoha matšoao a khatiso ebe laser e seha sekoere / khutlonnetsepa.