Galvo Laser Kulit Engraving Mesin motong pikeun Industri Sapatu

Modél No.: ZJ (3D) -160100LD

bubuka:

- Laser ukiran, perforating sarta motong bisa dipigawé dina hiji hambalan.

- Sistim nyetir ganda kalawan struktur rak gear.

- Sistim galvanometer dioptimalkeun.

- Kecepatan luhur sareng pamrosésan format ageung.

MANFAAT

Gancang

Sistem nyetir rak gear ganda gancang

Galvo & Gantry Integrasi

Gancang Galvo ukiran sarta format badag XY motong sumbu

Precision High

Ukuran sinar laser anu tepat dugi ka 0.2mm

Multi-fungsi

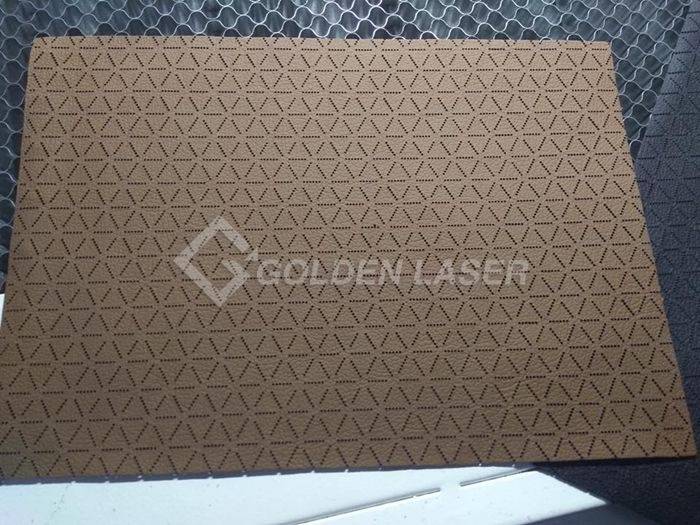

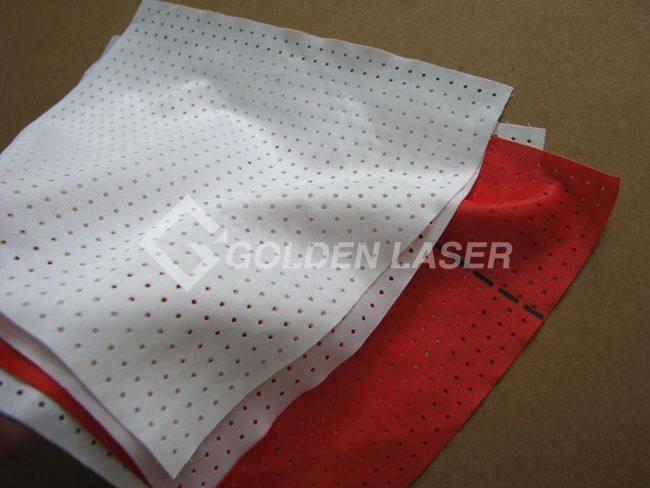

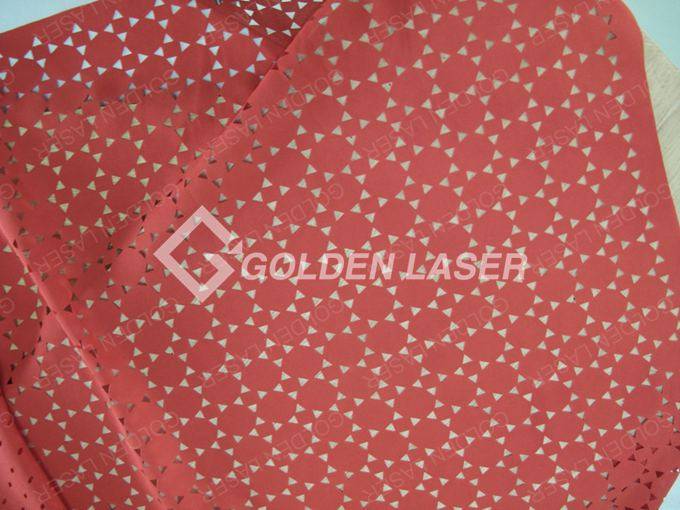

Engraving, perforating, hollowing, motong rupa-rupa kulit jeung tékstil

Fleksibel

Ngolah desain naon waé. Ngahémat biaya alat, ngahémat biaya tenaga kerja sareng ngahémat bahan

Otomatis

Otomatis laser processing roll pikeun roll berkat sistem conveyor na feeder otomatis

Demo Video - Kumaha Galvo Laser Mesin Gawé?

Ukiran laser, motong sareng perforating kulit langsung tina gulungan kalayan laju anu luhur.

Parameter Téknis

| Modél NO. | ZJ(3D)160100LD |

| Jenis laser | CO2 RF logam laser tube |

| Daya laser | 150W / 300W / 600W |

| Sistim Galvo | Sistim dinamis 3D, sirah laser galvanometer, aréa scanning 450 × 450mm |

| Daérah gawé | 1600mm×1000mm (62.9in×39.3in) |

| Méja gawé | Zn-Fe honeycomb vakum conveyor desain méja kerja |

| Sistem gerak | Servo motor |

| Sasayogian tanaga | AC220V ± 5% 50/60Hz |

| Konfigurasi standar | Suhu konstan chiller cai, kipas knalpot, compressor hawa |

| Konfigurasi pilihan | Feeder otomatis, alat filtrasi, wangunan sistem knalpot |

※Penampilan sareng spésifikasi tiasa robih kusabab pembaruan.

GOLDENLASER - Mesin laser pikeun Ihtisar Industri sapatu

| Produk | Jenis laser & kakuatan | Daérah gawé |

| XBJGHY160100LD bebas Dual Kepala Laser Mesin motong | CO2 kaca laser 150W × 2 | 1600mm×1000mm (62.9in×39.3in) |

| ZJ (3D) -9045TB Galvo Laser Engraving Mesin | CO2 RF logam laser 150W / 300W / 600W | 900mm×450mm (35.4in×17.7in) |

| ZJ (3D) -160100LD Galvo Laser Engraving Mesin motong | CO2 RF logam laser 150W / 300W / 600W | 1600mm×1000mm (62.9in×39.3in) |

| ZJ (3D) -170200LD Galvo Laser Engraving Mesin motong | CO2 RF logam laser 150W / 300W / 600W | 1700mm × 2000mm (66,9 inci × 78,7 inci) |

| CJG-160300LD / CJG-250300LD Kulit Asli Intelligent Nesting sareng Laser Cutting System | CO2 kaca laser 150W ~ 300W | 1600mm×3000mm (62.9in×118.1in) / 2500mm×3000mm (62.9in×98.4in) |

Multi-fungsi integrasi laser engraving, hollowing sarta motong kulit jeung lawon tina roll.

<Baca Langkung seueur ngeunaan sampel motong ukiran kulit laser

Mangga ngahubungan GOLDENLASER pikeun inpo nu leuwih lengkep. Tanggapan anjeun tina patarosan di handap ieu bakal ngabantosan kami nyarankeun mesin anu paling cocog.

1. Naon sarat processing utama anjeun? motong laser atawa laser engraving (nyirian) atanapi laser perforating?

2. Bahan naon anu anjeun peryogikeun pikeun prosés laser?

3. Naon ukuran jeung kandel bahan?

4. Saatos laser diprosés, naon bakal bahan dipaké pikeun? (industri aplikasi) / Naon produk ahir anjeun?

Atawa anjeun dealer atawa distributor pikeun mesin?