Ngaba unemibuzo okanye kukho imiba yobuchwephesha ongathanda ukuyixoxa? Ukuba kunjalo, wamkelekile ukuba uqhagamshelane nathi! Nceda ugcwalise le fomu ingezantsi. Iingcali zethu zihlala zikuvuyela ukunceda kwaye ziya kubuyela kuwe ngokukhawuleza.

Laser Cutting of Synthetic Textiles

Ukusetyenzwa kweLaser kuyafumaneka kumalaphu okwenziwa:

1. Ukusika iLaser

Amandla e-CO2 laser beam afunxwa lula ngelaphu lokwenziwa. Xa amandla e-laser aphezulu ngokwaneleyo, aya kunqumla ilaphu ngokupheleleyo. Xa usikwa nge-laser, amalaphu amaninzi okwenziwa aphuphuma ngokukhawuleza, okukhokelela kwimida ecocekileyo, egudileyo eneendawo ezincinci ezichaphazeleka kubushushu.

2. Umkrolo weLaser (uphawu lwelaser)

Amandla ombane we-CO2 we-laser anokulawulwa ukwenzela ukususa (ukukrola) izinto ezinzulu. Inkqubo yokukrola i-laser ingasetyenziselwa ukwenza iipateni ezintsonkothileyo kunye noyilo kumphezulu weempahla zokwenziwa.

3. Ukugqobhozwa kweLaser

I-CO2 laser iyakwazi ukugqobhoza imingxunya emincinci kwaye echanekileyo kumalaphu okwenziwa. Xa kuthelekiswa ne-mechanical perforation, i-laser inika isantya, ukuguquguquka, isisombululo kunye nokuchaneka. Ukugqojozwa kwelaphu kwelaphu kucocekile kwaye kucocekile, kuhambelana kakuhle kwaye akukho nkqubo ilandelayo.

Iingenelo zokusika amalaphu okwenziwa kusetyenziswa iilaser:

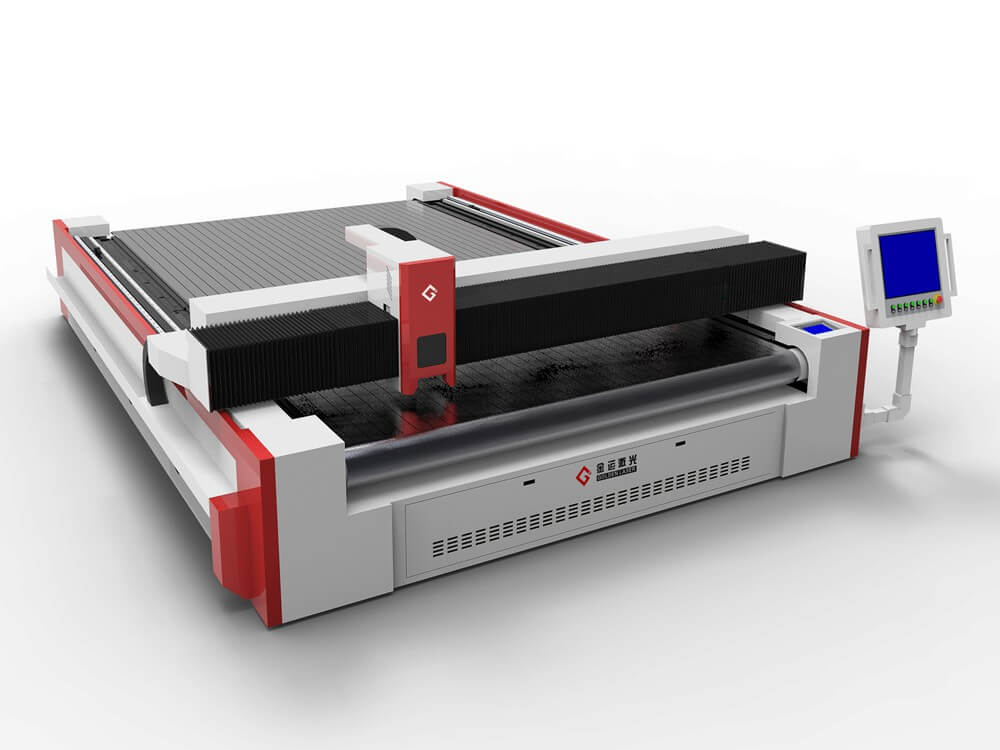

Izinto eziluncedo koomatshini bokusika belaser begolide kwilaphu:

Ulwazi oluphathekayo lokusikwa kwelaser yelaphu zokwenziwa:

Iintsinga ze-Synthetic zenziwe ngeepolima ezenziweyo ngokusekwe kwimathiriyeli ekrwada efana nepetroleum. Iindidi ezahlukeneyo zeentsinga ziveliswa kwiikhompawundi zeekhemikhali ezahlukeneyo. Ifiber nganye eyenziweyo ineempawu ezizodwa kunye neempawu ezihambelana nayo kwizicelo ezithile. Iintsinga ezine zokwenziwa -ipolyester, ipholyamide (inayiloni), i-acrylic kunye ne-polyolefin - ilawula imarike yempahla. Amalaphu e-Synthetic asetyenziswa kumashishini ahlukeneyo kunye namacandelo, kubandakanya, iimpahla, ifanitshala, ukuhluzwa, iimoto, i-aerospace, i-marine, njl.

Amalaphu e-Synthetic ahlala equlunqwe ngeeplastiki, ezifana ne-polyester, eziphendula kakuhle kakhulu kwi-laser processing. Umqa we-laser unyibilikisa la malaphu ngendlela elawulwayo, ekhokelela kwimiphetho engena-burr kwaye etywiniweyo.