Kugwiritsa Ntchito ndi Kudula Laser Njira Yopanda Fumbi

Nsalu yopukuta yopanda fumbi, yomwe imadziwikanso kuti nsalu yopanda fumbi, imapangidwa ndi 100% polyester yokhota pawiri yokhala ndi zofewa, zosavuta kupukuta malo okhudzidwa, kupaka popanda kuchotsa ulusi, kuyamwa bwino kwamadzi ndi kuyeretsa bwino. Kuyeretsa ndi kulongedza zinthu za nsalu zaukhondo kumachitika mumsonkhano waukhondo kwambiri.

Monga mtundu watsopano wa zinthu zopukuta mafakitale, nsalu zopanda fumbi zimagwiritsidwa ntchito makamaka kupukuta LCD, wafer, PCB, lens ya digito ya kamera ndi zinthu zina zapamwamba kwambiri popanda kupanga tinthu tating'onoting'ono ta fumbi, komanso zimatha kutsitsa tinthu tamadzi ndi fumbi kuti tikwaniritse kuyeretsa. zotsatira. Kugwiritsa ntchito nsalu zopanda fumbi kumaphatikizapo: tchipisi tating'onoting'ono ta semiconductor, microprocessors, etc.; mizere yopanga msonkhano wa semiconductor; ma disks, zinthu zophatikizika; Zowonetsa za LCD; mizere yopanga board board; zida zolondola, zida zamankhwala; mankhwala kuwala; makampani oyendetsa ndege, zida zankhondo; PCB mankhwala; ma workshop opanda fumbi, ma laboratories, etc.

Njira yachizolowezi yodulira nsalu yopukuta yopanda fumbi ndiyo kugwiritsa ntchito lumo lamagetsi kuti mudule mwachindunji; kapena kupanga nkhungu ya mpeni pasadakhale ndikugwiritsa ntchito makina okhomerera podula.

Laser kudulandi njira yatsopano yopangira nsalu zopanda fumbi. Makamaka nsalu yopanda fumbi ya microfiber, nthawi zambiri amagwiritsa ntchito laser kudula kuti asindikize bwino m'mphepete.Laser kudulandikugwiritsa ntchito mtengo wowunikira kwambiri wamphamvu kwambiri wa laser kuti usungunuke chogwiriracho, kuti zinthu zowunikira zimasungunuka mwachangu, zimasungunuka, zimayaka, zimayaka kapena kufika poyatsira, ndikuwulutsa zinthuzo mothandizidwa ndi kuthamanga kwa mpweya wothamanga kwambiri. mtengo, motero kuzindikira kudula kwa workpiece. Mphepete mwa nsalu zopanda fumbi zodulidwa ndi laser zimasindikizidwa ndi nthawi yomweyo kutentha kwapamwamba kusungunuka kuchokera ku laser, pokhala ndi kusinthasintha kwakukulu komanso kopanda kuyika. Chomaliza chodulidwa cha laser chikhoza kuchitidwa ndi mankhwala oyeretsera, zomwe zimapangitsa kuti pakhale mulingo wapamwamba wopanda fumbi.

Laser kudulaalinso ndi zosiyana zambiri poyerekeza njira ochiritsira kudula.Laser processingndiyolondola kwambiri, yachangu, yosavuta kugwiritsa ntchito komanso imakhala yokhazikika. Popeza laser processing alibe kukakamiza makina pa workpiece, zotsatira, mwatsatanetsatane ndi m'mphepete khalidwe la mankhwala odulidwa ndi laser ndi zabwino kwambiri. Komanso, alaser kudula makinaali ndi ubwino mkulu ntchito chitetezo ndi kukonza mosavuta. Nsalu yopanda fumbi yodulidwa ndi makina a laser okhala ndi kusindikiza m'mphepete mwawokha, opanda chikasu, osauma, osasweka komanso osasokoneza.

Kuonjezera apo, kukula kwa chomalizidwa chalaser kudulandizokhazikika komanso zolondola kwambiri. Laser imatha kudula mawonekedwe aliwonse ovuta ndikuchita bwino kwambiri ndipo motero kutsitsa mtengo, kumangofuna mapangidwe azithunzi pakompyuta. Kupanga prototypes ndi laser kudula kumakhalanso kwachangu komanso kosavuta.Laser kudulawa nsalu zopanda fumbi ndi wapamwamba kuposa njira wamba kudula kudutsa bolodi.

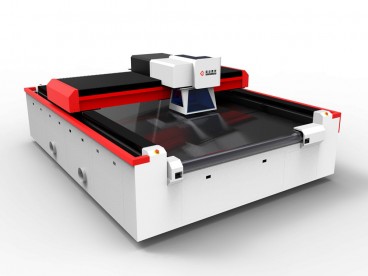

Zaposachedwalaser kudula lusoyopangidwa ndi Goldenlaser imakupatsirani njira yabwino kwambiri, yolondola komanso yopulumutsa zinthumakina odulira laser. Goldenlaser imaperekanso mayankho payekha ndi kukula kwa tebulo, mitundu ya laser ndi mphamvu, mitundu yodula mitu ndi manambala. N'zothekanso sintha ndimakina odulira laserndi zowonjezera zowonjezera modular malinga ndi zomwe mukufuna kukonza!