Zvishandiso uye Laser Kucheka Maitiro eDust-Yemahara Mucheka

Jira rekupukuta risina guruva, rinozivikanwawo sejira risina guruva, rakagadzirwa ne100% polyester kaviri weave ine nzvimbo yakapfava, iri nyore kupukuta nzvimbo dzinonzwa, kukwiza pasina kubvisa shinda, kunyura kwemvura kwakanaka uye kuchenesa. Kucheneswa uye kurongedza kwezvigadzirwa zvemachira akachena kunoitwa mumusangano wakachena kwazvo.

Serudzi rutsva rwemaindasitiri ekupukuta zvinhu, jira risina guruva rinonyanya kushandiswa kupukuta LCD, wafer, PCB, dijitari kamera lens uye zvimwe zvigadzirwa zvepamusoro-tech pasina kugadzira guruva, uye inogona zvakare kushambadza mvura uye guruva zvidimbu kuti uwane kuchenesa. effect. Kushandiswa kwemucheka usina guruva kunosanganisira: semiconductor yekugadzira line chips, microprocessors, nezvimwewo; semiconductor musangano kugadzira mitsetse; disc drives, composite zvinhu; LCD kuratidza zvigadzirwa; mitsara yekugadzira bhodhi redunhu; zviridzwa zvakarurama, midziyo yezvokurapa; optical products; indasitiri yendege, mauto anopukuta; PCB zvigadzirwa; maworkshop asina guruva, marabhoritari, nezvimwe.

Nzira yakajairwa yekucheka guruva-isina jira rekupukuta rinonyanya kushandisa chigero chemagetsi kutema zvakananga; kana kugadzira banga pachine nguva uye kushandisa punching muchina kucheka.

Laser kuchekainzira itsva yekugadzirisa jira risina guruva. Kunyanya iyo microfiber guruva-isina jira, kazhinji shandisa laser yekucheka kune yakakwana kumucheto chisimbiso.Laser kuchekaiko kushandiswa kweyakatarisana nepamusoro pesimba density laser danda kuvhenekesa iyo workpiece, kuitira kuti iyo yakakwenenzverwa ikurumidze kunyunguduka, kunyunguduka, kupisa kana kusvika painobatidza, uku ichifuridza zvinhu zvakanyungudutswa nerubatsiro rwekumhanya kwemhepo inoyerera coaxial kune iyo. danda, nokudaro kuona kucheka kweworkpiece. Mipendero yelaser-yakachekwa guruva-isina jira yakavharwa nekukasira kunyunguduka kwepamusoro-kunyunguduka kubva kune laser, uku iine yakakwira dhigirii yekuchinjika uye isina lining. Iyo yakapedzwa laser-yakatemwa chigadzirwa inogona kuurayiwa nekuchenesa kurapwa, zvichikonzera yakakwira guruva-isina mwero.

Laser kuchekainewo misiyano yakawanda kana ichienzaniswa neyakajairika nzira dzekucheka.Laser processingyakanyatsojeka, inokurumidza, iri nyore kushandisa uye ine otomatiki zvakanyanya. Sezvo laser processing isina kudzvanywa kwemechani pane workpiece, mhedzisiro, kunyatso uye kumucheto mhando yezvigadzirwa zvakachekwa nelaser zvakanakisa. Mukuwedzera, thelaser yekucheka muchinaine zvakanakira kuchengetedzwa kwepamusoro kwekushanda uye kugadzirisa kuri nyore. Jira risina guruva rakachekwa nemuchina welaser une otomatiki yekuisa chisimbiso, isina kutsvuka, isina kuomarara, isina kuputika uye isina kukanganisa.

Chii chimwe, ukuru hwechigadzirwa chakapedzwa chelaser cuttinginopindirana uye yakarurama kwazvo. Iyo laser inogona kucheka chero chimiro chakaomarara nekubudirira kwakanyanya uye nekudaro kudzikisira mitengo, ichida chete dhizaini yegraphic mukombuta. Kugadzira prototypes nelaser yekucheka zvakare nekukurumidza uye nyore kwazvo.Laser kuchekayemachira asina guruva akakwirira kune akajairwa kucheka nzira pabhodhi.

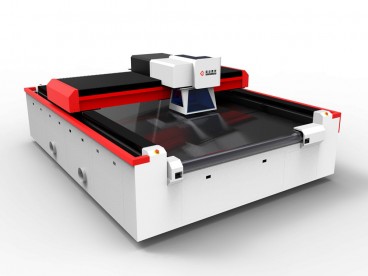

ZvichangoburwaLaser yekucheka tekinorojiyakagadziridzwa neGoldenlaser inokupa iwe inoshanda zvakanyanya, yakarurama uye inochengetedza zvinhulaser yekucheka michina. Goldenlaser inopawo zvigadziriso zvega neakagadziridzwa tafura saizi, laser mhando uye masimba, ekucheka misoro mhando uye manhamba. Izvo zvakare zvinogoneka kugadzirisa iyolaser yekucheka michinaine mamwe anoshanda modular ekuwedzera zvinoenderana neako ekugadzirisa zvaunoda!