Ukusetyenziswa kunye neLaser Cutting Inkqubo yelaphu elingenathuli

Ilaphu lokusula elingenathuli, elaziwa njengelaphu elingenathuli, lenziwe nge-100% ye-polyester ephindwe kabini kunye nomphezulu othambileyo, kulula ukusula iindawo ezinobuzaza, ukuhlikihla ngaphandle kokususa iintambo, ukufunxa kakuhle kwamanzi kunye nokucoca ngokufanelekileyo. Ukucocwa kunye nokupakishwa kweemveliso zelaphu ezicocekileyo kwenziwa kwiworkshop ecocekileyo kakhulu.

Njengohlobo olutsha lwezinto zokucima uthuli, ilaphu elingenathuli lisetyenziselwa ukosula i-LCD, iwafa, iPCB, ilensi yekhamera yedijithali kunye nezinye iimveliso zobuchwepheshe obuphezulu ngaphandle kokuvelisa amasuntswana othuli, kwaye inokubhengeza ulwelo kunye nothuli ukuphumeza ukucoca. isiphumo. Ukusetyenziswa kwelaphu elingenathuli libandakanya: iitshiphusi zomgca we-semiconductor, i-microprocessors, njl.; imigca yokuvelisa indibano ye-semiconductor; iidiski zokuqhuba, izinto ezidibeneyo; LCD iimveliso zokubonisa; imigca yemveliso yebhodi yesekethe; izixhobo ezichanekileyo, izixhobo zonyango; iimveliso zamehlo; ishishini lokubhabha, zosula emkhosini; Iimveliso zePCB; iiworkshops ezingenathuli, iilebhu, njl.

Indlela eqhelekileyo yokusika ilaphu lokusula uthuli ikakhulu ukusebenzisa isikere sombane ukusika ngokuthe ngqo; okanye ukwenza imela yokubumba kwangaphambili kwaye usebenzise umatshini wokubhoboza ukusika.

Ukusika kweLaseryindlela entsha yokulungisa ilaphu elingenathuli. Ngokukodwa ilaphu elingenathuli le-microfiber, lisetyenziswa ngokubanzi ukusika i-laser ukutywinwa komphetho ogqibeleleyo.Ukusika kweLaserkukusetyenziswa komqadi we-laser ogxininisekileyo wamandla aphezulu ukuntywila isixhobo sokusebenza, ukuze imathiriyeli elayidiweyo inyibilike ngokukhawuleza, ibe ngumphunga, itshise okanye ifikelele kwindawo yokutshisa, ngelixa ivuthela imathiriyeli etyhidiweyo ngoncedo lwesantya esiphezulu sokuhamba komoya ukuya kwi-coaxial. umqadi, ngaloo ndlela uqonda ukusika kwesixhobo sokusebenza. Imiphetho yelaphu le-laser-cut-dust-free cloth itywinwe ngokunyibilika kobushushu obuphezulu kwangoko be-laser, ngelixa inezinga eliphezulu lokuguquguquka kwaye akukho linting. Imveliso egqityiweyo ye-laser-cut ingenziwa ngokucoca unyango, okubangelwa umgangatho ophezulu ongenalo uthuli.

Ukusika kweLaserkananjalo ineeyantlukwano ezininzi xa kuthelekiswa neendlela eziqhelekileyo zokusika.Ukusetyenzwa kweLaserichaneke kakhulu, iyakhawuleza, kulula ukuyisebenzisa kwaye i-automation ephezulu. Kuba ukucutshungulwa kwelaser akunaxinzelelo lomatshini kwisixhobo sokusebenza, iziphumo, ukuchaneka kunye nomgangatho womphetho weemveliso ezisikwe ngelaser zigqwesile kakhulu. Ukongeza, iumatshini wokusika we-laserineenzuzo zokhuseleko oluphezulu lokusebenza kunye nokugcinwa lula. Ilaphu elingenathuli elisikwe ngomatshini welaser ngokutywinwa komphetho ngokuzenzekelayo, akukho tyheli, akukho kuqina, akukho fraying kwaye akukho ukuphazamiseka.

Ngaphezu koko, ubungakanani bemveliso egqityiweyo yeukusika laseriyahambelana kwaye ichaneke kakhulu. I-laser inokusika nayiphi na imilo entsonkothileyo ngobuchule obukhulu kwaye ngenxa yoko ithobe iindleko, ifuna kuphela uyilo lomzobo kwikhompyuter. Ukuphuhlisa iiprototypes nge-laser cutting nako kukhawuleza kwaye kulula kakhulu.Ukusika kweLaseryamalaphu angenalo uthuli luphezulu kwiindlela eziqhelekileyo zokusika kwibhodi.

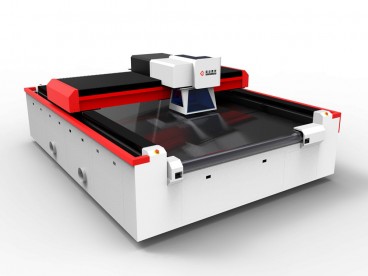

Okona kumvaiteknoloji yokusika i-laseriphuhliswe nguGoldenlaser ikunika eyona nto isebenzayo, ichanekile kwaye igcina izinto eziphathekayooomatshini bokusika laser. I-Goldenlaser ikwabonelela ngezisombululo zomntu ngamnye kunye nobukhulu betafile obucwangcisiweyo, iintlobo ze-laser kunye namandla, ukusika iintlobo zeentloko kunye namanani. Kuyenzeka kwakhona ukuqwalasela ioomatshini bokusika laserngezongezo zemodyuli ezisebenzayo ngokweemfuno zakho zokuqhubekekisa!